Ruida ha invertit molt de diners en construir un taller modern de producció automàtica.

En la línia completa de producció, des de la preparació del material, perforació, rectificació, tall, instal·lació, posada a punt fins a l'embalatge, diversos punts disposen d'equipaments d'alta gamma nacionals i estrangers per assolir una gran precisió i una taxa de zero defectes durant el procés de producció.

Les petites diferències en els materials primers tenen un impacte directe sobre la precisió de la màquina. Diferents tipus d'acer afecten directament la velocitat de funcionament i la vida útil de la màquina.

Les peces de fer es doblegaran i deformaran amb el temps, per tal de alleugerir la seva tensió, cal que es col·loquin en un entorn natural durant un any, s'estabilitzin i després es processin, cosa que pot millorar efectivament la qualitat i mantenir la màquina funcionant de manera estable.

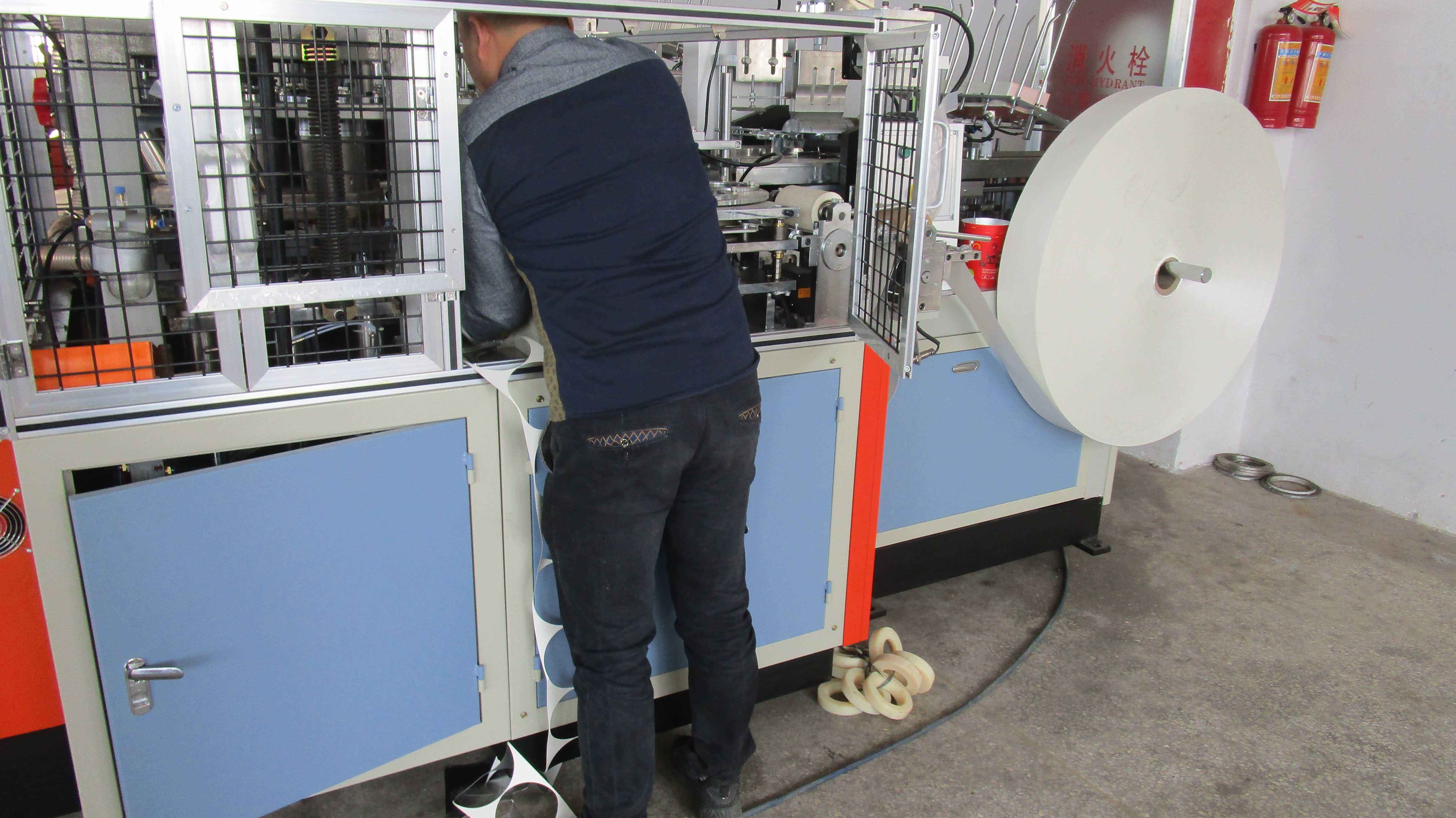

Tenim un equip professional de producció, instal·lació i posada en marxa.

L'experiència dels tècnics de posada a punt té més de deu anys, el que ofereix una garantia per al funcionament estable de la vostra màquina.

Ruida col·labora amb moltes marques elèctriques internacionals conegudes per aconseguir la formulació de producció més potent i crear una línia completa de màquines d'alta gamma per a gots de paper.

EN LÍNIA

EN LÍNIA