Den økende etterspørselen etter bærekraftig emballasje og Papirbolgemaskiner

Forbrukerens skifte mot bærekraft driver etterspørselen etter miljøvennlig emballasje

Mennesker prioriterer miljøvennlige valg, og omformer kjøpevaner. Bekymring for plastavfall og karbonutslipp driver denne utviklingen – spesielt i restauranter, supermarkeder. Spisesteder og butikker erstatter nå plast med plantebaserte alternativer som papirbolgemaskiner . Globale selskaper lover grønnere emballasjer, noe som øker etterspørselen etter komposterbare løsninger.

Regelverk for engangsplast akselererer markedsomstillinger

Over 130 land har forbudt/begrenset engangsplast siden 2020 (f.eks. EU-direktiv, Canadas forbud). Ikke-etterlevelse koster opptil 50 000 dollar per brudd. Økonomiske insentiver finnes for å bytte til grønne materialer. Produsenter omformer leverandkjeder og velger papirboller som funksjonelle, engangsersattninger. Regelverk har akselerert markedsendringer med 3–5 år.

Økende popularitet av biologisk nedbrytbare og komposterbare materialer i matemballasje

Fødevareleverandører prioriterer i stigende grad materialer, der balancerer funktionalitet med miljøansvar, hvilket har ført til en årlig vækst på 43 % i anvendelsen af kraftpapiræsker. Nøgleinnovationer inkluderer:

- Planteafledte PLA-lininger (polylactinsyre), der giver olie/fede modstandsevne, mens de bevarer komposterbarhed

- Vandbaserede barrierteknologier, der erstatter belægninger med PFAS

- FSC-certificeret papæske, der sikrer ansvarlig skovdrift. Disse materielle fremskridt gør det muligt for papæsker at nedbrydes på 90 dage i kommercielle komposteringsfaciliteter i modsætning til 450+ år for plastikalternativer. Overgangen til biologisk nedbrydelige materialer adresserer også forbrugersikkerhedsforhold, idet papæsker eliminerer risikoen for kemikalieleakage, som er forbundet med traditionelle plastikbeholdere.

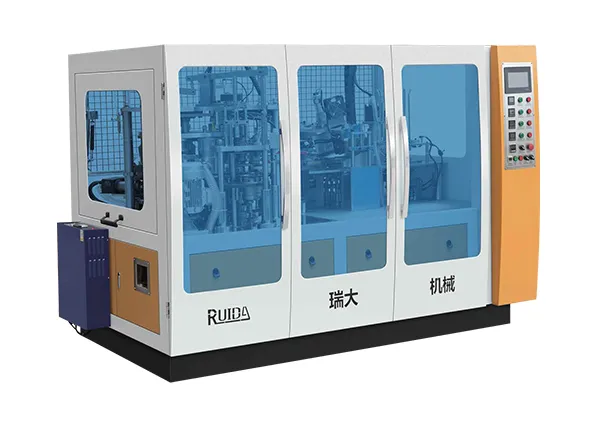

Hvordan plante- og papirbaserede emballagealternativer omformer industrierne

Bærekraftig emballasje endrer forretningsoperasjoner. Hurtigmatbransjen bruker papirskåler for å skille seg ut. Dagligvarebutikker bruker dem for å oppnå miljømål. Etterspørselen etter papirskåler øker, så produsenter trenger ny utstyr. ZheJiang RUIDA Machinery Co., Ltd. leder innen levering av skalerbare papirskålemaskiner. Matleveringstjenester krever komposterbare emballasjer, så engangskåler i papir øker med 27 % årlig. Papirvarer erstatter plast i sirkulære økonomimodeller.

Papirskålemaskin: Kjernte teknologi for effektiv og skalerbar produksjon

Forståelse av produksjonskapasitet og automatiseringsnivåer for papirskålemaskiner

Moderne bågmaskiner kan i dag produsere hvor mye som helst mellom 3 000 og 8 000 enheter hver time, og dette varierer ganske mye avhengig av hvor automatiserte de er. De halvautomatiske versjonene fungerer godt for små bedrifter som er i gang, siden de ikke koster så mye. Større operasjoner velger helautomatiserte oppsett med roboter som transporterer materialer og kontinuerlig sjekker kvaliteten under produksjonsløpene. Muligheten til å skru opp eller ned er virkelig viktig, fordi matleveringstjenester hadde en massiv vekst på 23 % globalt i fjor ifølge Statista-data fra 2024. Bedrifter trenger fleksible produksjonsalternativer for å følge med i disse markedssvingningene.

Nøkkelfunksjoner i moderne papirbågmaskiner

Lederprodusenter utstyrer maskiner med servodrevne formasjonssystemer som reduserer materialavfall med 15–20 % sammenlignet med hydrauliske modeller. Funksjoner inkluderer:

- Modulær design : Bytt stanser for å produsere 8–32 oz bølger uten nedetid

- Matkompatibel : Integrerte temperaturkontroller for PLA/PBAT bioplastbelegg

- Energieffektivitet : 30 % lavere strømforbruk enn eldre systemer

Integrasjon av papirskålmaskin i små produksjonsenheter

Kompakte maskiner med ️10 m² belegg gjør at entreprenører kan starte mikroenheter (5–10 tonn/måned kapasitet) nær bymessige forbrukssentre. Denne lokaliseringen reduserer logistikkostnader med 40 % og oppfyller samtidig kommunale plastforbud. Driftsansvarlige kan oppnå nullpunkt innen 12–18 måneder ved å rette seg mot QSR-kjeder og skykjøkken som trenger <50 000 skåler månedlig.

Materialer, belegg og sikkerhetsstandarder i bærekraftig papirskålfremstilling

FSC-sertifisert papir og kraftpapir som bærekraftige råvarer

FSC-sertifisert papir sikrer ansvarlig skogbruk; kraftpapir egner seg for matemballasje. Papirskålmaskiner (som RUIDAs) håndterer disse papirene i full fart. Store produsenter bruker FSC kraftpapp (motstår varm mat, fungerer med økologiske blekk).

PLA/PE belegg og fettresistente belegg i komposterbare matemballasjer

PLA-fôringar (plantebasert, komposterbare) og vassbaserte overtrekk (PFAS-fri) dominerer. RUIDA-maskiner bruker opp desse overtrekka nøyaktig. Polyetylen-overtrekk (prisvennlege, ikkje komposterbare) finst framleis, men minkar. Nye vassbaserte alternativ oppfyller streng regulering og tiltrekk seg produsentar.

Oppfylling av krav om PFAS-fri produksjon og mattryggleiksnormar

Regjeringar krev PFAS-fri emballasje. Papirschalar nyttar naturlege voks og vassbaserte overtrekk. Oppfylling av FDA/EU/ISO-standardar krev omfattande testing. RUIDA-maskiner sikrar at materiala held ut 100 °C utan lekasje av kjemikalier. Streng kvalitetskontroll (frå RUIDA) stadfest tryggleiken.

Regulatorisk samsvar og sertifiseringar for marknadstroverd

Essensielle kvalitetskontrollprosessar i produksjon av papirschalar

Kvalitetskontroll er kritisk. RUIDA-maskiner kontrollerer FSC-pappplattetykkjleik, fukt. Kamera overvakar formasjon av schalar; lekkasjetestar blir gjennomførte. Sluttkontroll: storleik, trykk, jamn overtrekk. Dette unngår uønska kontakt med mat, og falske påstandar om komposterbar produksjon.

Oppnådde EN13432 og ASTM D6400 for komposterbare emballasjer

Når produkter oppfyller internasjonale standarder som EN13432 fra Europa eller ASTM D6400 i Amerika, er det det som egentlig bekrefter at de brytes ned ordentlig. Å få sertifisering innebærer å gjennomgå tester i uavhengige laboratorier som viser at alt brytes ned helt i løpet av omtrent tre måneder inne i de store industrielle komposteringsanleggene, og viktig – ingenting skadelig blir igjen. Materialene må også bestå tester for tungmetaller, i tillegg til spesielle tester for å se hvor godt de brytes ned. Etter tolv uker på testbenken, skal minst nitti prosent av det som er igjen, bestå av biter som er mindre enn to millimeter i diameter. For selskaper som produserer ting som papirskåler med sine maskiner, blir det avgjørende å føre nøye oppføringer over hva som nøyaktig går inn i hver batch, hvis de ønsker å beholde de miljøvennlige sertifiseringene.

Miljøansvar for produkter (EPR) og globale overholdelsesrammeverk

Produsentansvar (EPR) gjelder i +40 land. Produsenter av papirschaler (som de som bruker RUIDA-maskiner) registrerer seg hos PRO Europe/US Plastics Pact. De finansierer innsamling/gjenbruk og overholder ISO 14021/EU-direktiv 94/62/EF. Ved ikke-overholdelse kan det medføre bøter på opptil 4 % av omsetningen.

Markedsmuligheter, lønnsomhet og oppskalering av en papirschal-virksomhet

Vekst i etterspørselen: Plastforbud og bymatleveringstrender

Verdensomspennende kampen mot plastavfall pluss den eksplosive veksten i matleveringsapper har virkelig skutt populariteten til papirbølger i været i det siste. Over 120 land har nå satt grenser for engangsplast, og vi ser også en massiv utvidelse av online matordring. Ekspertene innen emballasjeindustrianalyse spår en årlig vekst på rundt 8,9 prosent i denne sektoren helt fram til 2032. Byene tetter seg også raskere enn noen gang, med nesten sju av ti mennesker som skal leve i urbane områder midt i århundret ifølge FNs prognoser. Alle disse faktorene sammen betyr at det er et stort businesspotensial for selskaper som produserer papirbølger spesielt til restaurantkjeder og de takeout-leveringstjenestene som alle elsker så mye disse dager.

Bærekraftige emballasjeløsninger for restauranter og hurtigmatbutikker

Leverandører av matvarer prioriterer økende miljøvennlig emballasje for å møte forbrukernes forventninger og regulatoriske krav. Kjedsrestauranter (QSRs) representerer et viktig vekstsegment, med mange kjeder som har forpliktet seg til 100 % bærekraftig emballasje innen 2025. Papirbølger tilbyr ideelle løsninger gjennom:

- Tilpassbare brandingalternativ

- Egenskaper for varmebevarelse

- Lekkasjesikre design

- Kompatibilitet med varierte kjøkken

Kostnadsstruktur, fortjenestemarginer og skalerbarhet for små papirbølgeenheter

Opprinnelige investeringer i papirbølgeanlegg gir typisk 25–40 % bruttfortjenestemarginer ved små produksjonsenheter. Driftskostnadene fordeler seg på:

| Kostnadskomponent | Prosent | Merknader |

|---|---|---|

| Råmaterialer | 45–50 % | FSC-sertifisert papir dominerer |

| Arbeid | 15–20 % | Redusert gjennom automasjon |

| Bransjearbeid | 10–12 % | Energieffektive maskiner senker dette |

| Vedlikehold | 8-10% | Rutinemessig vedlikehold minimerer nedetid |

Moderne papirbolgemaskiner gjør det mulig å skalere operasjoner, noe som tillater produksjonskapasitetsøkninger på 200–300 % gjennom modulære utvidelser. Denne fleksibiliteten hjelper produsenter med å utnytte regionale plastforbud mens de opprettholder lønnsomhet.

Innholdsfortegnelse

-

Den økende etterspørselen etter bærekraftig emballasje og Papirbolgemaskiner

- Forbrukerens skifte mot bærekraft driver etterspørselen etter miljøvennlig emballasje

- Regelverk for engangsplast akselererer markedsomstillinger

- Økende popularitet av biologisk nedbrytbare og komposterbare materialer i matemballasje

- Hvordan plante- og papirbaserede emballagealternativer omformer industrierne

- Papirskålemaskin: Kjernte teknologi for effektiv og skalerbar produksjon

- Materialer, belegg og sikkerhetsstandarder i bærekraftig papirskålfremstilling

- Regulatorisk samsvar og sertifiseringar for marknadstroverd

- Markedsmuligheter, lønnsomhet og oppskalering av en papirschal-virksomhet