Ruida latissime patens possibilitatum ac solutionum copiam praebere potest. Nostra series machinarum vasi papirei technologia praecellente orbis terrarum instructa est, qua varia genera vasorum papireorum efficiendi iuvatur. Haec producta clientes nostros praevolare suis aequalibus in qualitate producti, materiae atque specificationibus sinunt.

Vasa papiri ex pulvere ligneo chemico ex papiri primo fabricata sunt, coniuncta per machinationem, vasculo papireo in oris vasorum forma, productum semel utendum. Ad comparationem ad alia vasa papiri in foro, vasa papiri Ruida...

Patinas quadratas spatium magis efficientes sunt ad platingendum, idoneas ad mensas parvas et cibos magnos, aut ad quadratas sartas vapores aut fructus sicos. Ad cibos vel vascula quae formam specificam requirunt, forma quadrata fortasse melior erit...

Cista papiri est genus necessarii vitae amici et hygienici, facta ex papiri, cum levitate, durabilitate et aliis commodis. Ad comparationem ad vasa et patinas papiri, maiorem capacitatem habet et saepe utitur...

With world-leading technology and control of craftsmanship details, you can find Ruida's unique advantages:

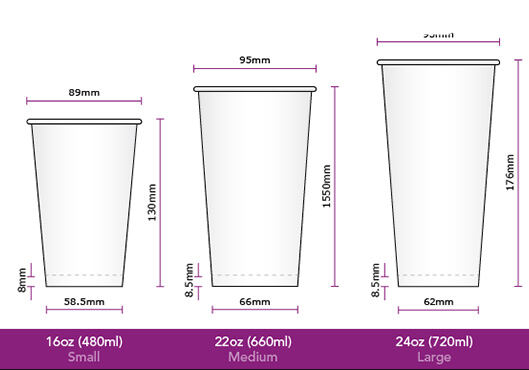

Una machina in mercato tantummodo vasa papirea 4-9 uncias/4-12 uncias conficere potest; nos autem ex 2-16 uncias/16-22 uncias/22-32 uncias facere possumus, et os maximi catini papirei usque ad 300 mm pervenire potest.

Nos exactas conditiones pro orillo flexo, fundo plicato vel cannelatura vasorum papireorum habemus. Saepe prima electio quorundam magnorum vel catenarum marcharum factoriarum OEM, ut Starbucks, McDonald's, etc.

Compared to other brand machines which can only produce PE coated paper, our machine is suitable for a wider range of paper materials, such as PLA/non-plastic coated paper etc. in addition, the paper thickness we can make is also wider.

There are many details to consider when designing the finished size, of which market acceptance is the most important. Our team of professional designers will work with you to confirm the specifications and produce a prototype for mould design approval.

The production process begins with the selection of high quality paper materials, which are then moulded into paper cups using precision machinery. Each finished product undergoes rigorous testing to ensure durability and performance.

Postquam approbatae sunt, tazze papireae in magnis quantitatibus conficiuntur ad desideria clientium explenda. Hoc exacto opere efficitur ut quaeque tazza papirea leges artis et opiniones clientium adimpleat.

Online

Online