Ruida poate oferi o gamă largă de soluții și posibilități. Seria noastră de mașini pentru pahare din hârtie dispune de o tehnologie la nivel mondial, care vă ajută să produceți o varietate de produse diferite. Aceste produse vor permite clienților noștri să fie în avans față de concurenți în ceea ce privește calitatea produselor, materialele și specificațiile.

Paharele din hârtie sunt fabricate din pulpa chimică de lemn, realizată din hârtie brută. Prin prelucrare mecanică și lipire se obține un recipient din hârtie, având aspectul buzei în formă de pahar, fiind un produs unică. Comparativ cu alte pahare din hârtie disponibile pe piață, paharele Ruida au...

Bolurile pătrate sunt mai eficiente din punct de vedere al spațiului la servire, fiind potrivite pentru utilizarea atunci când mesele sunt mici și farfuriile sunt mari, sau pentru tăvi pătrate cu aburi sau recipiente pentru fructe uscate. Pentru feluri de mâncare sau recipiente care necesită o anumită formă, forma pătrată poate fi mai potrivită...

Găleata de hârtie este un tip de necesitate igienică, prietenoasă cu mediul și convenabilă, fiind realizată în principal din hârtie, având avantajele unei greutăți reduse și durabilității. Comparativ cu paharele și bolurile din hârtie, are o capacitate mai mare și este adesea utilizată...

Cu o tehnologie avansată la nivel mondial și un control riguros al detaliilor de mestesug, veți descoperi avantajele unice Ruida:

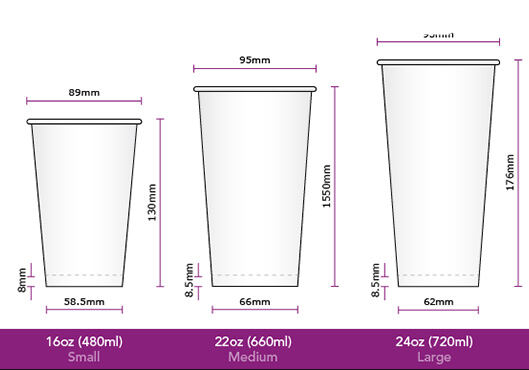

O mașină obișnuită de pe piață poate realiza doar pahare din hârtie de 4-9 uncii/4-12 uncii, iar noi putem realiza de la 2-16 uncii/16-22 uncii/22-32 uncii, iar diametrul maxim al tigăii din hârtie poate atinge 300 mm.

Avem cerințe detaliate pentru marginea îndoită, fundul pliat sau canelura paharelor din hârtie. Adesea prima alegere a unor fabrici OEM ale unor mărci mari sau lanțuri, cum ar fi Starbucks, McDonald's etc.

Comparativ cu alte mașini ale altor mărci care pot produce doar hârtie cu strat de PE, mașina noastră este potrivită pentru o gamă mai largă de materiale pentru hârtie, cum ar fi hârtia cu strat de PLA/neplastic etc. În plus, grosimea hârtiei pe care o putem realiza este, de asemenea, mai variată.

La proiectarea dimensiunii finale trebuie luate în considerare multe detalii, dintre care cea mai importantă este acceptarea produsului pe piață. Echipa noastră de designeri profesioniști va colabora cu dumneavoastră pentru a confirma specificațiile și va produce un prototip pentru omologarea designului matricei.

Procesul de producție începe cu selecția unor materiale de hârtie de înaltă calitate, care sunt apoi modelate în pahare de hârtie cu ajutorul unor echipamente precise. Fiecare produs finit este supus unor teste riguroase pentru a garanta durabilitatea și performanța.

După aprobare, paharele de hârtie sunt produse în masă pentru a satisface cererea clienților. Acest proces riguros asigură că fiecare pahar de hârtie respectă standardele din industrie și așteptările clientului.

ONLINE

ONLINE