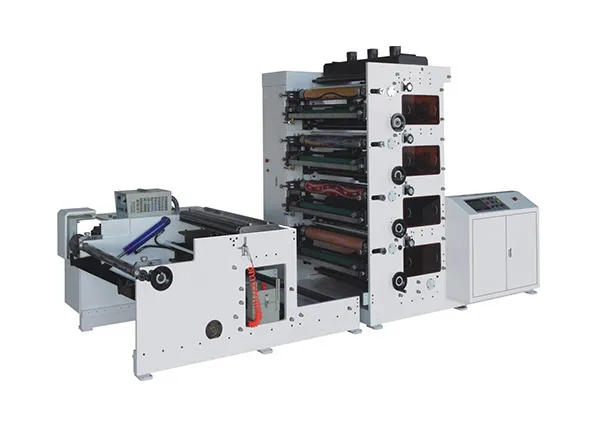

Flexographic printing presses serve as the core production equipment in the modern packaging printing industry. With their exceptional adaptability and highly efficient, stable performance, they have become the preferred printing solution across numerous sectors. These presses can be widely applied to diverse substrates such as plastic films, self-adhesive labels, corrugated cardboard, and aseptic packaging, perfectly meeting the varied packaging printing demands of industries including food, daily chemicals, and pharmaceuticals. Moreover, flexographic printing presses offer significant economic and environmental advantages: their high-speed, stable printing capability combined with rapid plate-changing technology substantially boosts production efficiency for medium-to-long runs, effectively reducing per-unit costs. Simultaneously, they support both water-based and UV inks, aligning with green environmental trends while achieving high-definition halftone print quality. This truly unifies high-efficiency production with sustainable development. Today, flexographic printing technology has become a vital driving force for enhancing quality, boosting efficiency, and advancing industrial upgrading within the packaging printing sector.