Important parameters:

Speed: 140-160 pcs/min

Paper Cup Size: 4-24 oz

Product Application

Core equipment for industrial-grade intelligent paper cup production line

• Physical isolation between workbench and transmission system: The forming unit and the longitudinal shaft transmission structure (gear + CAM indexing mechanism) are arranged in layers to effectively reduce vibration interference

• Closed oil bath lubrication system: All transmission parts are lubricated in a shower-like manner to ensure >8,000 hours of trouble-free operation

• Quick-release mold workbench: Patented lock design enables mold replacement in 3 minutes, and cleaning and maintenance efficiency is increased by 60%

✓ Photoelectric tracking system, real-time monitoring of 32 production process nodes

✓ Servo precision bottom paper feeding (repeat accuracy ±0.3mm), with optional machine vision inspection (AI defective product rejection rate 99.8%)

Applicable cup type: 4oz~24oz (market cup/milk tea cup/ice cream cup)

Optional configuration:

• Automatic stack counting device

• QR code laser marking module

• Cloud production data management

|

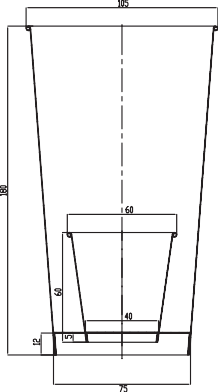

Cups Specifications |

4-24oz |

|

Forming size |

Cup Top Diameter 60-105mm |

|

Cup Bottom Diameter 40-75mm |

|

|

Cup Height 60-138mm/138-180mm |

|

|

Paper Specifications |

170-350g/m² |

|

Available Paper material |

Single and double PE/PLA/Non plastic coated paper |

|

Production Speed |

140-160 pcs/min |

|

General Power |

15KW |

|

Weight |

3200kg |

|

Air source |

0.6m³/min |

|

Packing Dimension |

2900*1510*2200mm |

ONLINE

ONLINE