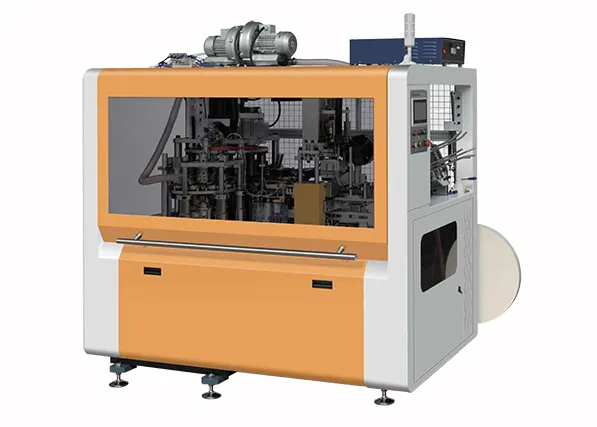

Understanding the Role of a Paper Cup Machine in Modern Business Operations

How a Paper Cup Machine Can Boost Business Efficiency

Modern paper cup machines have revolutionized paper cup manufacturing by automating most tasks. These machines drastically reduce manual labor compared to older methods (though the extent varies by setup). A paper cup machine handles forming, sealing, and packaging in one go. Factories can produce around 100 cups per minute with minimal waste. Companies gain better schedule control, crucial for holidays or sudden large orders. Newer paper cup machine models have built - in diagnostics to spot issues (like misalignments) before delays. Marketing teams benefit from quick design tweaks without new molds. Startups thrive too—they can start small and scale up without new machinery, all thanks to a versatile paper cup machine.

Evaluating Cost Efficiency of a Low Operating Cost Paper Cup Making Machine

Breakdown of Energy, Labor, and Material Costs in Paper Cup Production

Today’s paper cup machines cut major expenses: electricity, labor, and waste. Newer models slash energy use by 18–25% (vs. old machines) via advanced servo motors (per Energy Star 2023). Personnel costs drop 60–70%—automatic paper cup machines shape and stack cups without constant human help. Material waste? Smart sensors and precision cutting keep scrap rates under 3% (a big win over traditional methods).

| Cost Component | Traditional Production | Automated Machine | Savings |

|---|---|---|---|

| Energy | $1.20 per 1k cups | $0.85 per 1k cups | 29% |

| Labor | $4.50 per 1k cups | $1.40 per 1k cups | 69% |

| Materials | 8–12% waste rate | 2–3% waste rate | 63% |

Comparative Analysis: Outsourcing vs. In-House Production with a Low Operating Cost Paper Cup Making Machine

For companies outsourcing their cup manufacturing, the numbers tell quite a story. Medium sized operations shell out around 740 thousand dollars each year according to Ponemon research from last year. When businesses switch to running their own automated cup making lines, they cut those expenses down by roughly 42 percent. Most find themselves back at even money point somewhere between twelve and eighteen months after installation. What's really interesting is how much cheaper it gets when looking at ongoing expenses. The cost of keeping machines running plus training staff only eats up about six to eight percent of what it costs to own the whole setup. Compare that to dealing with outside vendors where unpredictable fees can take anywhere from twenty five to thirty percent straight off the top every month.

Essential Features of a High-Performance Paper Cup Machine

Automated Forming, Bottom Sealing, and Delivery Systems

High - performance paper cup machines use automation to boost throughput and cut manual work. Key parts:

- Rotary forming stations with precision-curling technology for consistent cup shaping

- Heat-activated sealing units that bond cup walls and bases at 165–185°C

- Servo-driven conveyor belts delivering 65–80 cups/minute to downstream packaging

PLC modules coordinate these steps—enabling 24/7 production and 37% labor cost cuts (Packaging Efficiency Report 2023).

Adjustable Molds for Multiple Cup Sizes and Designs

Top-tier machines offer interchangeable mold sets supporting 4–12oz capacities, with quick-release mechanisms allowing size changes in under 15 minutes. Dual-density polyethylene compatibility ensures seamless switching between hot and cold beverage cup configurations. This versatility eliminates the need for multiple specialized units, saving $14k–$23k in capital and maintenance costs.

Integration with Digital Control Panels and Fault Diagnostics

Modern paper cup machines have digital panels showing real - time metrics (like OEE). Sensors detect vibrations/heat, sending predictive maintenance alerts. Built - in error codes (100–150 options) let operators fix jams/alignment fast. A 2023 study found 90% faster troubleshooting vs. analog systems. Remote support? Saves $5k–$7k/year in lost production per machine.

By prioritizing these features, manufacturers hit ROI in 14–19 months—all thanks to a smart paper cup machine.

Matching Machine Capacity to Business Demand for Scalable Growth

Small-Scale vs. Industrial-Scale Paper Cup Machine Output Ranges

Paper cup machine capacity varies widely. Entry - level models make 800–1,200 cups/hour (Food Packaging Report 2023). Small businesses (local cafes) need 2,000–4,000 cups/day—these machines work. Larger ops? Regional distributors need machines making 65,000+ cups/day.

Future-Proofing Your Investment With Modular Machine Designs

Modular paper cup machines let you expand capacity gradually. Add forming stations/sealing units as business grows—cutting upfront costs by 32% (vs. buying large machines early). A standard line (8 hours/day) can run 24/7 with add - ons (auto feeders, longer conveyors). This flexibility handles busy seasons and fuels growth.

Choosing a Paper Cup Machine Supplier: Trusted Manufacturers

Innovation + Reliability: ZheJiang RUIDA Machinery Co.,Ltd

Pick suppliers like ZheJiang RUIDA Machinery Co.,Ltd—they advance automation with PLC controls, IoT diagnostics, and precision servos in their paper cup machines. These cut waste by 23% and ensure consistent quality—minimizing stoppages.

Warranty + Support for Paper Cup Machines

Look for suppliers (like ZheJiang RUIDA) offering:

- Minimum 3-year warranties on core components

- 24/7 remote troubleshooting with response times under 4 hours

- On-site operator certification programs that reduce human error by 31%

Verified spare parts availability is essential—facilities without it face 170% longer replacement cycles, according to 2024 packaging industry studies.

Affordability + Durability: Long - Term Value of Paper Cup Machines

Don’t just look at upfront costs. ZheJiang RUIDA’s paper cup machines use hardened steel—lasting 40% longer than cheap alternatives. Regular maintenance cuts unscheduled downtime below 5%. Companies prioritizing quality (like ZheJiang RUIDA) save 27% more over 3 years.

Table of Contents

- Understanding the Role of a Paper Cup Machine in Modern Business Operations

- Evaluating Cost Efficiency of a Low Operating Cost Paper Cup Making Machine

- Essential Features of a High-Performance Paper Cup Machine

- Matching Machine Capacity to Business Demand for Scalable Growth

- Choosing a Paper Cup Machine Supplier: Trusted Manufacturers