Paper Cup Machine: How Improper Setup Compromises Cup Quality

A staggering 23% of production defects in paper cup manufacturing stem from improper machine configuration (Packaging Trends Report 2023). Operators often underestimate how critical precise setup parameters are for maintaining cup integrity and minimizing material waste.

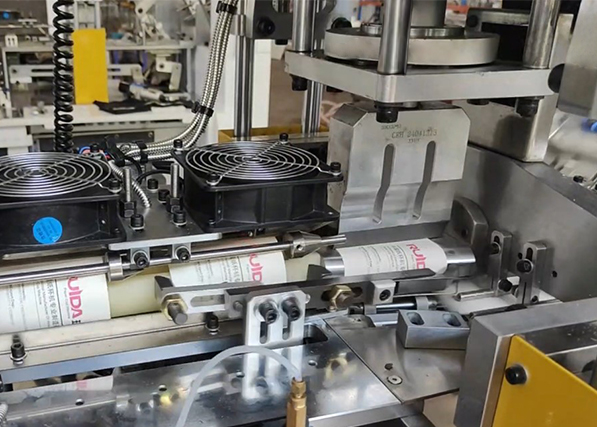

Incorrect Adjustment for Cup Size and Shape Leading to Double Cupping and Misshapen Output

When die cutters and forming tools aren't calibrated properly for specific cup sizes, it often leads to problems like overlapping layers what we call double cupping plus all sorts of shape irregularities. Just a small 2mm error at the blanking station can really mess things up, cutting down on good product quality by around 40% when running at top speeds. The experts who study materials have seen this happen time and again too they point out that if the material isn't distributed evenly throughout the forming process, the resulting cups just don't hold up as well on those side walls. That kind of weakness shows up in testing and ultimately affects how long products last before needing replacement.

Mismatched Molds and Forming Stations Causing Uneven Pressure and Structural Defects

Using outdated molds with newer forming stations creates pressure inconsistencies during thermoforming, leading to thin spots (Ꮠ¨0.3mm thickness variance) and seam gaps exceeding 0.5mm tolerance thresholds. These setup errors account for 34% of leak-related product returns in foodservice packaging.

Case Study: Production Errors at a Mid-Sized Packaging Plant Due to Incorrect Configuration

A Wisconsin-based converter experienced 18% scrap rates after upgrading their paper cup machine without reconfiguring auxiliary systems. The $92,000 retrofit revealed legacy PLC programming couldn’t synchronize with new servo-driven forming stations, causing 7-second cycle time discrepancies.

Following Manufacturer Guidelines for Optimal Paper Cup Machine Setup

Adhering to calibration protocols reduces setup-related defects by 61% on average. Key steps include performing torque checks on clamping mechanisms (25–35 N·m), validating temperature uniformity across heating plates (±2°C), and conducting test runs with calibration paper before full production.

Material Handling Issues Affecting Production Efficiency

Conveyor Belt Malfunctions Leading to Jams and Inconsistent Feed Rates

Getting the conveyor system right is absolutely critical for Paper Cup Machines if they're going to keep running at their best. When belts get out of alignment or rollers start showing wear, it creates those annoying gaps between cups that eventually lead to frustrating jams. According to some industry data I've seen, around 15 to 22 percent of unexpected stoppages in cup production actually come down to problems with these conveyors. Most of the time, it's because maintenance folks didn't check the tension properly or there was just too much dirt buildup getting in the way. That's why experienced operators always make sure to look at how the belts are tracking and adjust the torque settings regularly. Keeping materials moving smoothly through the machine isn't just nice to have it's basically what makes high volume production possible in the first place.

Using Low-Quality Paper Stock That Increases Jamming and Downtime

Substandard paper rolls with inconsistent thickness or moisture content compress unevenly during forming, increasing jamming risks. Thin or brittle stock fails under heat and pressure, causing misfeeds. Operators must verify paper GSM ratings and moisture levels (ideally 6–8%) before loading to prevent disruptions.

Balancing High-Speed Operation With Reliable Material Handling in Modern Paper Cup Machines

Modern systems operating at 200–300 cups per minute demand synchronized coordination between feeders, rollers, and forming stations. Overloading conveyors or mismatching speed settings creates bottlenecks. Implementing servo-driven synchronization and automated load monitoring allows manufacturers to maximize throughput while reducing mechanical strain.

Mold Degradation and Thermal Control Failures

Worn or damaged molds reducing cup consistency and increasing waste

The constant heating and cooling cycles really take a toll on molds over time. Small flaws on the surface can actually boost production waste by anywhere between 12 to 18 percent. Industry reports show that around two thirds of early mold changes happen because parts expand differently when heated. These tiny cracks create problems with wall thickness throughout the product. Packaging inspections have noticed that roughly 4% of all beverage containers end up leaking somewhere down the line, which means significant losses for manufacturers who deal with these issues regularly.

Incorrect heating settings compromising cup strength and seal integrity

Maintaining precise temperature differentials between forming zones is critical—paper heated above 160°C loses 34% of its natural binding agents within 30 cycles. Operators often overlook how ambient humidity affects required thermal input, leading to weak sidewall seals that fail standard pressure tests 23% more frequently.

Data insight: 68% of deformation defects linked to thermal imbalance (Source: ZheJiang RUIDA Machinery Co.Ltd technical report)

An analysis of 4,200 production batches revealed nearly 7 in 10 misshapen cups originate from <2°C deviations in mold temperature profiles. Localized overheating near ejection pins causes asymmetric cooling rates—a flaw detectable via infrared imaging but often missed in routine inspections.

Implementing preventive mold inspection and temperature calibration protocols

Leading manufacturers conduct daily infrared scans of operating molds and biweekly resistance tests on heating elements. A three-stage calibration protocol developed for paper cup machines shows promise—early adopters report 41% fewer thermal-related stoppages through real-time PID controller adjustments and predictive wear modeling.

Sensor and Control System Errors Increasing Downtime

Faulty sensors causing empty dispensing and unnecessary machine stoppages

Modern paper cup machines rely on optical and pressure sensors to monitor material flow and alignment. When these malfunction, machines may dispense without paper, disrupting production. Research indicates sensor failures account for 23% of unplanned downtime in packaging systems, with false alarms reducing hourly output by 15–20%.

Electrical control failures disrupting continuous operation of the Paper Cup Machine

Power surges and aging relay components frequently destabilize programmable logic controllers (PLCs). A 2023 analysis found 62% of control-related downtime stems from voltage fluctuations damaging motor drivers, forcing multiple system reboots per shift and causing inconsistent heating and misfired pneumatic controls.

Emerging trend: IoT-enabled diagnostics for early detection of electronic issues

Progressive manufacturers now integrate vibration sensors and thermal imaging cameras that stream performance data to cloud platforms. This technology identifies anomalies like abnormal current draw or deteriorating insulation weeks before failure. Early adopters report a 32% reduction in electrical-system downtime through predictive maintenance alerts generated by machine learning algorithms.

Inadequate Maintenance and Operator Training Practices

Neglecting routine cleaning and maintenance as a leading cause of breakdowns

Failure to follow scheduled maintenance accounts for 38% of unplanned downtime. Machines not cleaned daily from forming debris face a 23% higher risk of hydraulic valve failures. Lack of lubrication in high-friction components accelerates wear by up to 400%, often necessitating costly mold replacement.

Essential maintenance checklist for reliable Paper Cup Machine performance

Operators should implement a three-tiered maintenance strategy:

- Daily: Clean heating elements, inspect pneumatic valves, verify adhesive nozzle alignment

- Weekly: Calibrate temperature sensors, check belt tension, test emergency stop functions

- Monthly: Replace worn gaskets, analyze motor vibration patterns, conduct vacuum system leak tests

Training operators to prevent errors and respond effectively to malfunctions

Comprehensive training programs reduce operational errors by 67% when combining classroom instruction with machine simulations. Trained operators resolve 89% of minor sensor faults without technician assistance, maintaining production continuity.

Proactive servicing strategies to minimize unplanned downtime

Implementing predictive maintenance through thermal imaging of electrical panels identifies 92% of potential component failures before they occur. Scheduled bearing replacements based on operational hour counters—rather than reactive repairs—decrease emergency costs by 54%.

FAQ Section

What are common issues in paper cup manufacturing?

Common issues include improper machine setup, material handling inefficiencies, mold degradation, and sensor or control system errors.

How can machine setup affect cup quality?

Improper calibration of machine parts can lead to defects like double cupping, misshapen products, and uneven pressure during formation, which compromises the structural integrity of cups.

What role does material handling play in production efficiency?

Efficient material handling is crucial for minimizing jams and ensuring consistent feed rates, which are essential for maintaining high-volume production.

How can thermal control failure impact cup quality?

Incorrect heating settings may weaken cup strength and integrity, leading to sealing failures and increased deformation defects.

What maintenance practices can improve machine reliability?

Routine cleaning, component calibration, and operator training can significantly reduce downtime and improve overall machine reliability.

Table of Contents

-

Paper Cup Machine: How Improper Setup Compromises Cup Quality

- Incorrect Adjustment for Cup Size and Shape Leading to Double Cupping and Misshapen Output

- Mismatched Molds and Forming Stations Causing Uneven Pressure and Structural Defects

- Case Study: Production Errors at a Mid-Sized Packaging Plant Due to Incorrect Configuration

- Following Manufacturer Guidelines for Optimal Paper Cup Machine Setup

- Material Handling Issues Affecting Production Efficiency

-

Mold Degradation and Thermal Control Failures

- Worn or damaged molds reducing cup consistency and increasing waste

- Incorrect heating settings compromising cup strength and seal integrity

- Data insight: 68% of deformation defects linked to thermal imbalance (Source: ZheJiang RUIDA Machinery Co.Ltd technical report)

- Implementing preventive mold inspection and temperature calibration protocols

- Sensor and Control System Errors Increasing Downtime

- Inadequate Maintenance and Operator Training Practices

- FAQ Section