Implementing Preventive Maintenance for Extended Machine Lifespan

Understanding Preventive Maintenance in Paper Cup Machine Operations

Regular maintenance for paper cup machines means checking things out on schedule, greasing parts when needed, and swapping out worn components before something breaks down completely. This is different from waiting until something actually breaks and then fixing it, which can cost a lot more time and money. Studies show that sticking to regular maintenance routines cuts down unexpected stoppages by about two thirds and keeps machines running longer, maybe even doubling their useful life according to industry reports from last year. What technicians typically do includes making sure belts are tight enough but not too tight, checking if molds line up properly, and applying oil to gears so they don't wear out as fast. These simple steps help protect expensive parts such as the forming heads and cutting blades that take the most beating during operation.

Daily, Weekly, and Monthly Preventive Tasks for Optimal Performance

Adopt a tiered maintenance schedule to balance productivity and machine health:

- Daily: Clean paper debris from molds and conveyor belts, inspect heating elements for temperature consistency.

- Weekly: Test safety sensors, lubricate roller bearings with food-grade grease, and check pneumatic systems for air leaks.

- Monthly: Calibrate cup wall thickness settings, replace worn gripper belts, and inspect electrical connections for corrosion.

This structured approach prevents 85% of common failures such as motor burnout or misaligned seals.

Reactive vs. Preventive Maintenance: Best Practices for B2B Production Units

| Criteria | Preventive Maintenance | Reactive Maintenance |

|---|---|---|

| Annual Repair Costs | $12k (predictable) | $28k (variable) |

| Downtime Impact | 8—12 hours/month | 25—40 hours/month |

| Component Lifespan | 5—7 years | 3—4 years |

Preventive strategies reduce lifecycle costs by 35% for B2B manufacturers while maintaining ISO-certified production continuity. Facilities combining IoT-enabled vibration sensors with manual inspections achieve 92% fewer emergency repairs compared to reactive-only operations.

Routine Cleaning and Proper Lubrication of Key Components

Step-by-step daily cleaning procedures for paper cup machines

Starting every shift should involve turning off all equipment first, then clearing away any paper bits stuck in the feed mechanisms and around where stacks build up. Give all visible parts a good wipe down using microfiber cloths so sticky stuff doesn't accumulate, particularly near where glue gets applied. When dealing with really stubborn gunk, reach for solvents that the manufacturer recommends and apply them carefully with soft bristled brushes to keep from damaging anything. Facilities that schedule thorough cleanings once a week instead of just sticking to daily routines see about an 18 percent drop in unexpected shutdowns. Makes sense when thinking about long term maintenance costs versus quick fixes.

Critical parts requiring regular cleaning: molds, rollers, and belts

- Molds: Clean forming cavities after each material changeover using isopropyl alcohol wipes

- Rollers: Inspect daily for paper dust accumulation, rotating components to access hidden surfaces

- Conveyor belts: Remove static-charged particles with anti-static cleaners to maintain proper cup alignment

Selecting high-quality lubricants and proper application on gears and bearings

| Lubricant Type | Best For | Certification Required |

|---|---|---|

| Food-grade grease | Gearboxes | NSF H1 |

| Synthetic oil | High-speed bearings | ISO 6743-4 |

| Dry film | Plastic contact areas | FDA 21 CFR 178.3570 |

Apply lubricants sparingly using precision syringes, focusing on manufacturer-specified grease points in drive chains and cam followers. Over-lubrication attracts paper dust, creating abrasive slurries that accelerate component wear.

Inspecting and Maintaining Critical Mechanical Components

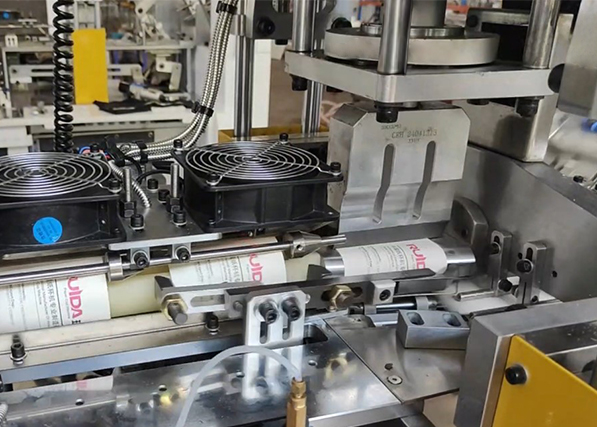

Identifying wear and replacing belts, bearings, and conveyor systems

During paper cup manufacturing operations, belts, bearings and conveyor systems face continuous strain day after day. Regular checks on these parts aren't just good practice they're essential for maintaining production quality. When drive belts start showing signs of wear, alignment issues can creep in affecting machine accuracy by as much as 40% according to recent studies from Industrial Equipment Journal last year. Damaged bearings tend to work harder too, pushing motor loads up between 15% and 20%. Weekly inspections should focus on spotting early warning signs like fraying edges, hairline cracks or uneven wear spots across all components. Parts running past their recommended service life need special attention since they're more likely to fail unexpectedly when least expected.

Calibrating forming, cutting, and molding mechanisms for precision

Misaligned forming dies or cutting blades cause 34% of dimensional defects in paper cups. Use laser alignment tools quarterly to verify tolerances within ±0.1 mm, adjusting gear meshing and pneumatic pressures to maintain consistent cup wall thickness.

Maintaining heating systems to ensure consistent cup formation

Temperature fluctuations exceeding ±5°C in sealing zones lead to adhesive failures in 1 out of 8 production batches. Clean heating elements daily to remove paper residue and validate thermocouple accuracy monthly using infrared sensors.

Case Study: Reducing downtime through component overhaul in a mid-sized plant

A Midwest paper cup manufacturer implemented quarterly overhauls of forming mechanisms and conveyor chains, reducing unplanned downtime by 62% over 18 months. Scheduled replacements of high-wear parts during planned maintenance windows increased annual throughput by 1.2 million units.

Electrical System Maintenance and Predictive Technology Integration

Routine checks for wiring, circuit boards, and common electrical failures

Regular electrical inspections prevent 19% of industrial equipment failures caused by wiring issues (NFPA 2023). Technicians should:

- Inspect wire insulation weekly for fraying or scorch marks

- Clean circuit boards monthly using antistatic brushes to remove dust buildup

- Test emergency stop circuits quarterly using multimeter continuity checks

Common failures like loose terminal connections or capacitor degradation account for 37% of unplanned downtime in packaging machinery. A 2024 predictive maintenance study found plants using thermal imaging cameras to detect overheating components reduced electrical repairs by 42% annually.

Leveraging IoT sensors for predictive maintenance in paper cup machines

Modern IoT systems track vibration patterns, motor currents, and temperature fluctuations to forecast component wear. For instance, a Midwest cup manufacturer retrofitted machines with vibration sensors and cut bearing replacement costs by $14,000/year through early failure detection (IEEE 2023 case data).

Key integration steps include:

- Installing wireless sensors on motors, drives, and heating elements

- Configuring alerts for abnormal power draw fluctuations

- Syncing data with CMMS platforms for automated work orders

Plants using this hybrid approach typically achieve 89% first-time repair success rates versus 63% with manual diagnostics, according to packaging industry benchmarks.

Following Manufacturer Guidelines and Tracking Maintenance Records

Adhering to Manufacturer-Recommended Service Intervals and Care Protocols

The lifespan of paper cup machines really depends on following those manufacturer maintenance schedules religiously. When companies actually stick to what the original equipment makers recommend, they're addressing the specific wear issues that happen in those fast moving parts responsible for forming and sealing cups at speed. A recent study from the packaging industry back in 2023 showed something interesting too. Plants that followed all those recommended service intervals saw their unexpected breakdowns drop by about 37%, which is pretty impressive when compared to places that just fix things when they break down. Some important maintenance actions worth noting are:

- Verifying alignment of internal maintenance calendars with OEM manuals

- Using only approved cleaning agents for polymer-coated components

- Documenting torque specifications during bolt replacements to prevent over-tightening

Digital vs. Manual Maintenance Logs for Efficient Service History Tracking

Modern facilities increasingly adopt cloud-based CMMS (Computerized Maintenance Management Systems) that automatically track filter changes or belt tension adjustments. These systems reduce human error by 53% compared to paper logs (Packaging Technology Review 2022). Critical advantages include:

- Real-time alerts for overdue tasks through integrated IoT sensors

- Predictive analytics identifying recurring sealant heater failures

- Simplified audit trails for ISO 9001 compliance

While manual logs suffice for smaller operations, digital tracking ensures seamless knowledge transfer during technician turnover and enables trend analysis across multiple machines.

FAQs

What is preventive maintenance in paper cup machine operations?

Preventive maintenance involves scheduled checks, lubrication, and replacement of parts before failure occurs, ensuring cost savings and extended machine lifespan.

How often should preventive maintenance be performed?

Maintenance should follow a tiered schedule: daily cleaning and inspections, weekly lubrication and safety checks, and monthly calibrations and replacements.

What are the benefits of preventive over reactive maintenance?

Preventive maintenance reduces repair costs, downtime, and extends component lifespan compared to the more expensive and disruptive reactive maintenance approach.

How does IoT contribute to predictive maintenance?

IoT sensors monitor vibration, temperature, and motor currents to predict and prevent component failure, enhancing maintenance efficiency.

Table of Contents

- Implementing Preventive Maintenance for Extended Machine Lifespan

- Routine Cleaning and Proper Lubrication of Key Components

- Inspecting and Maintaining Critical Mechanical Components

- Electrical System Maintenance and Predictive Technology Integration

- Following Manufacturer Guidelines and Tracking Maintenance Records

- FAQs