How a Paper Cup Machine Works: Core Mechanism and Operational Principles

Step-by-Step Breakdown of the Paper Cup Machine Working Process

ZheJiang RUIDA’s Paper Cup Machine transforms flat paper sheets into finished cups via key steps. First, pre-coated paper rolls load into the system. A special cutting area then shapes these materials into basic cup walls and bottoms. Next, rotating plates curl the walls into cylindrical forms in the curling stage. To keep cups dry inside, the Paper Cup Machine applies heat sealing at ~150°C using PE adhesive. This creates a watertight seal between each cup’s bottom and sides. After sealing, another component curls the top edges inward for extra strength. Finally, completed cups exit the line—sometimes at 150 per minute—ready for conveyor belt packaging.

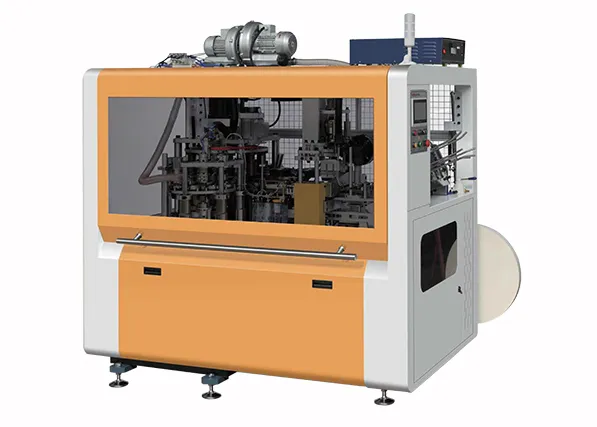

Core Components Driving Machine Performance

Four critical components ensure precision and efficiency:

- Programmable Logic Controllers (PLCs) coordinate motion across 20+ axes

- Servo-driven feeders align materials with ±0.2 mm accuracy

- Infrared heating systems maintain consistent sealing temperatures

- Photoelectric sensors detect defects at 120 frames/second

These systems work synergistically to reduce waste by 15–20% compared to manual operations while maintaining 99.5% production uptime.

Role of Automation in Modern Paper Cup Machine Operation

Modern paper cup machines use IoT for smart predictive maintenance. Sensors send live vibration data to the cloud, alerting staff 48–72 hours before issues. Machine vision checks seal gaps (>0.1 mm defects get rejected), ensuring FDA 21 CFR Part 176 compliance. Automated lubrication cuts maintenance by 80%. Energy recovery captures 40% of production heat, supporting sustainability.

Types of Paper Cup Machines: Automatic, Semi-Automatic, and Manual

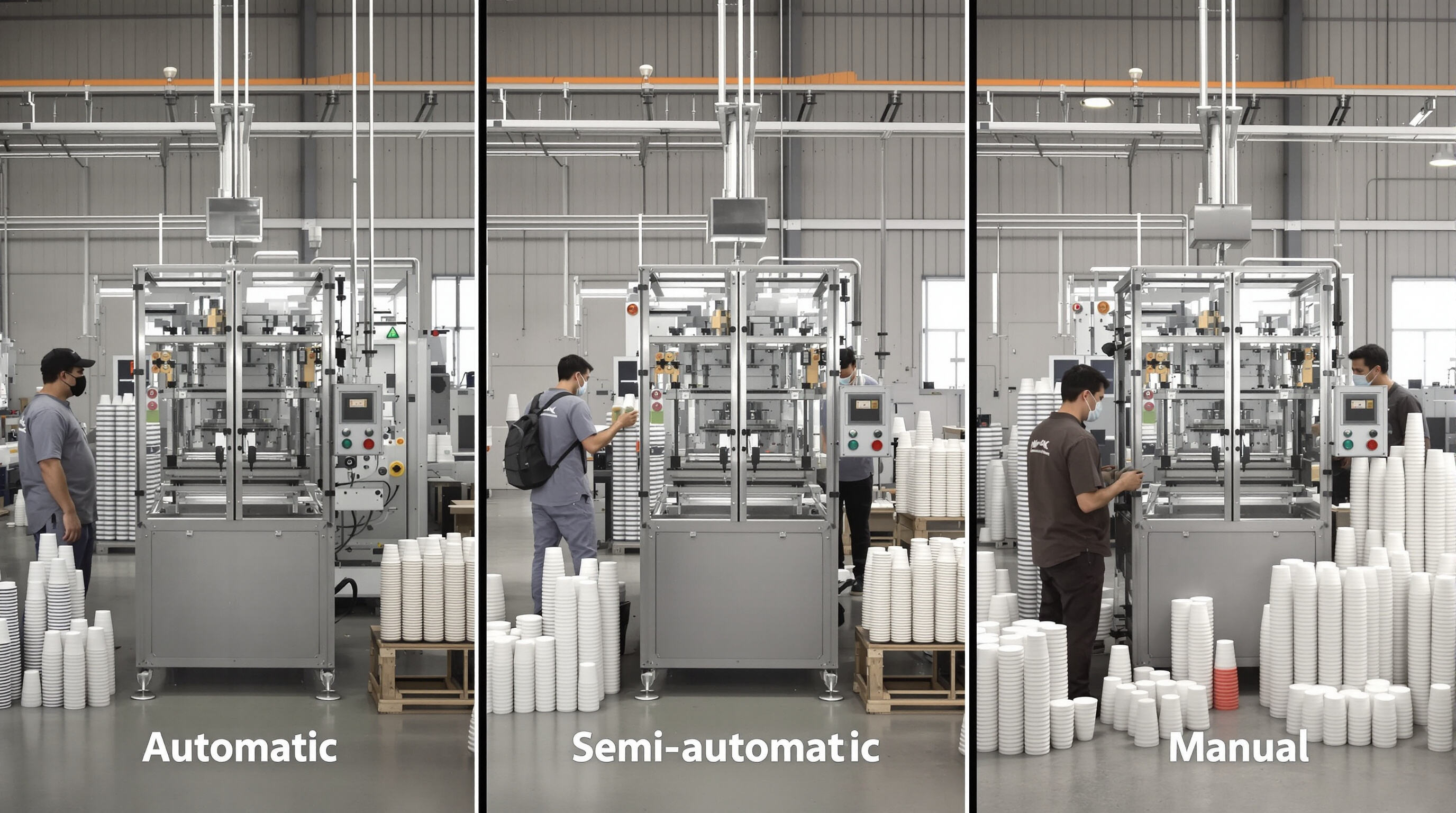

Comparative Analysis of Automation Levels and Machine Types

Paper cup machines are categorized by automation level, with operational efficiency and labor demands varying significantly across types:

| Machine Type | Automation Level | Output Capacity (cups/minute) | Labor Required | Ideal Use Case |

|---|---|---|---|---|

| Automatic | Full | 60–150 | Minimal | Large-scale production |

| Semi-Automatic | Partial | 30–50 | Moderate | Medium-sized operations |

| Manual | None | 5–20 | High | Small workshops |

Automatic paper cup machines (e.g., from ZheJiang RUIDA Machinery Co.,Ltd) dominate high-volume work, using PLCs for precision. Semi-automatic balances cost and flexibility. Manual suits startups/niche markets.

Semi-automatic models combine automated processes such as die-cutting with manual steps like cup assembly, offering flexibility for businesses scaling production incrementally. While output rates are lower, they balance cost and efficiency for mid-tier demand.

Manual machines rely entirely on operator skill, making them suitable for startups or niche markets with limited budgets. Though labor costs and error rates rise, they provide an entry point for small-batch manufacturing.

Modern factories increasingly adopt automated systems to meet sustainability goals and comply with food safety regulations, reducing material waste by 12–18% compared to manual methods.

Materials and Processes in Paper Cup Machine Production

Materials Used in Paper Cup Production (Biodegradable, PLA-Coated, Recyclable)

Today's paper cup machines handle mainly three kinds of materials these days. First there's the traditional stuff we've seen for years - paper coated with polyethylene. Then comes PLA coated biodegradable paper made from corn starch, which has really taken off since around 2022. The foodservice industry alone saw a jump of about 37% in its use because these cups work well with compost systems. For those looking at recyclable alternatives, manufacturers have developed versions without any plastic layers at all. These rely on water based barriers instead. But here's the catch: making them requires special processing steps on the paper cup machines to keep the cups strong enough when hot liquids are poured into them.

Key Manufacturing Processes: Die Cutting, Slitting, and Forming

- Die Cutting: Machines stamp cup bottoms and sidewalls from coated paper rolls with ±0.2 mm precision.

- Slitting: Rotary blades cut paper into strips matching cup height specifications while maintaining waterproof layer integrity.

- Forming: Heated mandrels (120–160°C) shape cups while pressure-sealing seams—a process requiring <2% tolerance in modern automated systems.

Sustainability, Regulatory Compliance, and Eco-Friendly Innovations

Under the EU’s Single Use Plastics Directive, 70% of cups will need compostable liners by 2024. ZheJiang RUIDA Machinery Co.,Ltd uses IoT sensors to cut polymer waste by 29% (vs. 2020). New nano-cellulose coatings work with existing machines, no costly upgrades.

Technological Advancements and Industry Applications of Paper Cup Machines

Latest technological trends in paper cup manufacturing machinery

Modern paper cup machines use servo motors/PLCs, boosting speed by 25% per cycle. Energy waste drops by 18% (Packaging Digest 2023). Integrated systems handle die cutting, sealing, and forming automatically. Eco - friendly models work with biodegradable PLA and recyclable paper, keeping waste <2%. Enhanced HMIs let operators adjust cup size/wall thickness via touchscreens.

Integration of IoT, cloud systems, and machine vision

IoT - connected paper cup machines share real - time data (motor temps, glue thickness) via cloud dashboards, cutting downtime by 30%. Machine vision detects flaws (200 cups/second, 99% accuracy), ensuring food safety (PFAS - free materials). Real - time quality data flows to central hubs for instant fixes.

Closing: The Future of Paper Cup Machines

As sustainability and efficiency demands grow, paper cup machines (like those from ZheJiang RUIDA Machinery Co.,Ltd) will lead innovation. Their role in eco-friendly, high-speed production ensures lasting relevance in packaging.