Understanding Automation Levels in Paper Bowl Machines

How Automation Defines Paper Bowl Machine Functionality

Automation transforms paper bowl machines. Semi-automatic models need manual feeding/removal. Fully automatic ones handle all steps: feeding, shaping, pressing, output. Consistency matters—automatic machines hit ±0.1mm specs (servo motors, PLCs). Semi-automatic? ±0.5mm. For large batches, this ensures quality control.

Core Differences Between Semi-Automatic and Fully Automatic Paper Bowl Machines

| Feature | Semi-Automatic | Fully Automatic |

|---|---|---|

| Output Capacity | 500 bowls/hour | 3,000–6,000 bowls/hour |

| Labor Required | 2–3 operators | 0–1 operator |

| Process Integration | Manual handling between stages | End-to-end automation |

| Changeover Time | 30+ minutes | <5 minutes |

Fully automatic systems deliver up to 12x higher throughput by eliminating manual bottlenecks. Integrated quality sensors also reduce defects by 18% compared to semi-automatic models, based on 2023 packaging industry benchmarks.

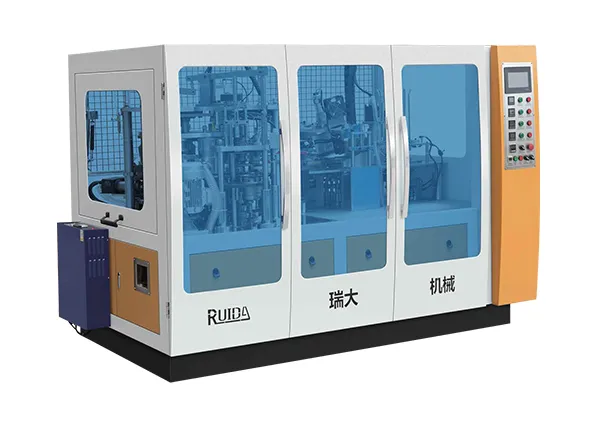

Case Study: Leading Manufacturer's Automation Offerings

A leading manufacturer (ZheJiang RUIDA) showcased automation. A customer switched to RUIDA’s fully automatic line: capacity tripled, labor dropped 67%. Real-time monitoring adjusted settings, cutting waste by 22%. This shows why automation boosts output, cuts costs, and ensures consistency—outpacing traditional methods.

Production Capacity and Output: Matching Machine Type to Demand

Output Speed Comparison: 300 vs. 6,000 Bowls per Hour

Semi-automatic paper bowl machines typically produce 250–350 bowls per hour, requiring 3–5 operators for feeding and inspection. In contrast, fully automatic models achieve 5,500–6,200 bowls hourly with minimal oversight, using PLC-controlled forming and rotary punching.

| Machine Type | Output Range (Bowls/Hour) | Labor Required | Ideal Use Case |

|---|---|---|---|

| Semi-Automatic | 250–350 | 3–5 operators | Startups, small bakeries |

| Fully Automatic | 5,500–6,200 | 0–1 operator | Large food chains, OEM suppliers |

Automatic systems eliminate manual molding and curing steps, closing a 20x productivity gap. According to the 2024 Food Packaging Trends Report, semi-automatic models average 15–20% material waste versus 8–12% in automated lines due to precision hydraulic pressing.

When High Volume Justifies an Automatic Paper Bowl Machine

Three factors signal the need for automation:

- Daily demand exceeding 10,000 bowls: Automatic machines recoup their $120k–$180k cost within 18–24 months at this scale.

- Labor cost instability: Automation reduces labor expenses by 40–60%, crucial in high-wage regions.

- Quality consistency needs: Automatic machines cut dimensional defects by 55%, maintaining 1.5mm tolerance versus 3–5mm in semi-automatic models.

Industry experts recommend automatic systems for facilities producing over 10,000 units daily, where manual processes become inefficient. Modular automatic lines also support seasonal demand fluctuations without halting production.

Cost Analysis and Return on Investment for Paper Bowl Machines

Upfront Investment: Semi-Automatic vs. Fully Automatic Machine Costs

Fully automatic paper bowl machines cost $180,000–$250,000–2–3 times more than semi-automatic models ($60,000–$90,000)–due to integrated quality control sensors and servo-driven forming systems. Despite the higher entry cost, semi-automatic machines remain popular among small operations; 78% of facilities with sub-500k annual capacity use them, per 2023 industry data.

Long-Term ROI of Automatic Paper Bowl Machines

Automated systems reduce per-unit operating costs by 35–50% through:

- 80% lower labor needs (1 operator vs. 5)

- 12–18% less material waste via precision forming

- 3–4x faster production speeds

These efficiencies typically yield full ROI within 18–24 months. A 2024 case study found automatic machines achieved $2.7M in lifetime savings over semi-automatic alternatives through optimized maintenance and 99.2% uptime.

Is Higher Initial Cost Worth It? Balancing Budget and Efficiency

The breakeven point for automation is around 800,000 annual units. Below this, semi-automatic machines offer lower upfront costs despite higher per-unit expenses. Key considerations include:

| Factor | Automatic Advantage | Semi-Auto Advantage |

|---|---|---|

| Labor Costs | 85% reduction | Lower initial investment |

| Energy Consumption | 22% higher | Standard efficiency |

| Production Scalability | Unlimited | Capped at ~300k/yr |

For businesses planning 15–20% annual growth, automatic paper bowl machines provide essential scalability without frequent equipment upgrades.

Labor, Quality, and Operational Efficiency by Automation Level

Labor Requirements: Reducing Headcount with Automation

Fully automatic paper bowl machines reduce manual labor by 70–85% compared to semi-automatic systems. While semi-automatic setups require 3–4 workers for forming, sealing, and inspection, automatic models operate with just one supervisor. This efficiency allows teams to redirect labor to maintenance or innovation, supporting round-the-clock production.

Product Uniformity: How Automatic Paper Bowl Machines Improve Quality

Automation eliminates human variability in shaping and sealing. Servo-driven systems maintain ±0.2mm accuracy across 6,000 bowls/hour–90% more consistent than manual operations. Uniform pressure application reduces leaks by 3.8x while meeting FDA food safety standards.

Case Study: Quality Defect Reduction After Automation Upgrade

A midwestern packaging supplier transitioned from semi-automatic to automatic paper bowl machines, achieving:

- 89% drop in dimensional rejects (from 8% to 0.9%)

- 67% fewer returns for sealing issues

- 4.1x improvement in production consistency

The investment paid for itself in 14 months through reduced waste and unlocked premium contracts requiring 1% defect rates.

Future-Proofing with RUIDA’s Paper Bowl Machines

Analysts project 74% adoption of RUIDA-style automatic paper bowl machines by 2025 (IoT, AI maintenance). Emerging standards: energy efficiency (<3% variance), minimal waste (<0.8%). These deliver 22% faster ROI (carbon credits). For businesses aiming to stay competitive, RUIDA’s paper bowl machines offer the automation, quality, and scalability needed to thrive.

Table of Contents

- Understanding Automation Levels in Paper Bowl Machines

- Production Capacity and Output: Matching Machine Type to Demand

- Output Speed Comparison: 300 vs. 6,000 Bowls per Hour

- When High Volume Justifies an Automatic Paper Bowl Machine

- Cost Analysis and Return on Investment for Paper Bowl Machines

- Labor, Quality, and Operational Efficiency by Automation Level

- Future-Proofing with RUIDA’s Paper Bowl Machines