The Role of Automatic Paper Cup Machines in Mass Production

Understanding the Integration of Automatic Paper Cup Machines and Their Role in Mass Production

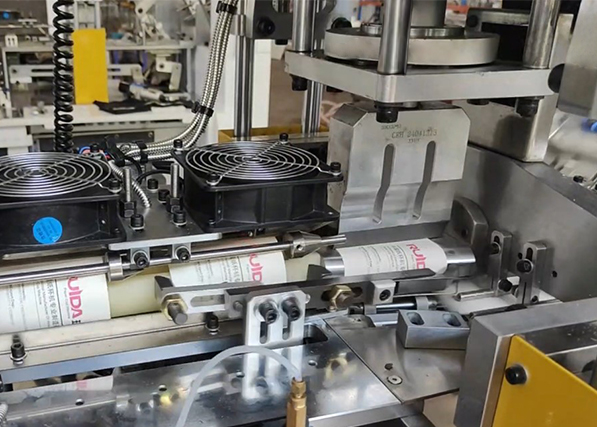

The automatic paper cup machine has changed how things are made in the industry, bringing together all steps from feeding raw materials to printing designs, forming cups, and checking quality in one efficient system. These machines cut down on the need for workers to do repetitive tasks manually, which means products come out looking the same every time. That's really important for companies making cups for restaurants and cafes, especially since they need to meet strict cleanliness rules and often handle large orders. When people aren't touching the cups as much during production, there's less chance of germs getting onto them. This helps manufacturers stay within FDA guidelines for food safety without having to worry so much about accidental contamination issues popping up.

How High-Speed Paper Cup Production Meets Growing Market Demands

The worldwide market for disposable cups is expected to hit around $7.8 billion by 2025 according to Verified Market Reports. This growth comes mainly from takeaway orders increasing at about 23% each year through food delivery services. Factory owners are turning to fast automated paper cup machines that can churn out anywhere from 80 to 150 cups every single minute. These machines make it possible to fill large orders quickly and let companies keep up with changing packaging styles throughout different seasons. What used to take days now happens in just hours when it comes to updating cup designs for holidays or special promotions.

Case Study: Scaling Output with Automated Systems

One major manufacturer boosted their ability to scale operations after implementing totally automated systems. These new setups cut down on production stoppages by around 62%, while getting nearly perfect consistency at 98.5% for all those 12 ounce cups they make. The company also installed IoT sensors throughout the facility. These smart devices keep tabs on things like how tight the paper is running and whether the glue is at just the right temperature. Because of this constant monitoring, they manage to save about 18% on materials every year. What's really impressive though is how these tech upgrades let factories crank out 2 to 3 times more product without needing extra workers or spending significantly more on electricity bills.

Trend Analysis: Rising Adoption of Automation in Paper Cup Manufacturing

Asia-Pacific and North America together make up around 74% of all automatic paper cup machine installs according to LinkedIn stats from 2023. This growth is mostly because people want eco-friendly packaging options these days. Looking at the bigger picture, we generated something like 36 million tons of plastic waste back in 2020 as reported by the EPA. That's gotten manufacturers thinking seriously about switching to paper products instead. Going automated helps with this green shift while also paying off quicker than semi-auto machines. Factories report seeing returns on investment about 22% faster when they go fully automated. Why? Well, the workflow gets much smoother which cuts down production costs between 9 and 14% per unit when running at scale.

Enhanced Efficiency and Precision Through Automation

Modern automatic paper cup machines deliver unmatched consistency and address scalability challenges in mass production environments.

Reducing Human Error with Automatic Paper Cup Machine Operations

Automated systems eliminate variability in cup forming and sealing, achieving 99.8% dimensional consistency across batches. Programmable logic controllers (PLCs) reduce quality control rejects by 40–60% compared to manual operations, significantly improving yield and product reliability.

Achieving 80–85 Cups Per Minute: Data Insights into Machine Efficiency

Top-tier models sustain outputs of 82 cups per minute (±2) using optimized feeding systems and simultaneous multi-cup processing. This represents a 300% productivity gain over semi-automatic machines, enabling single-shift production of more than 39,000 units. Such performance ensures timely delivery of large-scale orders without compromising quality.

Balancing Initial Investment and Long-Term Gains in Automation Efficiency

Automated systems can produce around 80 to 85 items every minute with pretty consistent results, staying within half a millimeter accuracy on about 98 out of 100 runs. The improved precision cuts down on wasted materials by roughly 12 to 15 percent according to recent studies shared on LinkedIn back in 2023. Most manufacturers find their money comes back within 18 to 24 months from these cost reductions alone. Plus, modern machines are built with energy efficiency in mind, so they don't consume much power at all. We're talking about less than 23 kilowatt hours for each batch of 10 thousand units made, as noted in the latest manufacturing cost analysis report from 2024.

Workflow Optimization and Production Line Integration

Streamlining Manufacturing With Production Line Automation

Paper cup machines that run fully automatic really streamline operations when they handle printing, forming, and sealing all at once. When workers don't have to move products from one station to another manually, this saves time and keeps everything running smoothly. Some factories report cutting down on downtime around 40%, which makes a big difference over time. The best systems these days come equipped with those PLC controllers that help keep things flowing evenly through the production line and stop those annoying bottlenecks from happening. A recent study in the Packaging Efficiency Report showed something interesting too real time tweaks to heat settings and pressure levels can cut down on wasted materials somewhere between 18% and maybe even 22%. That kind of efficiency matters for both bottom line savings and environmental impact.

Key Features of Fully Automatic Paper Cup Machines That Optimize Workflow

Leading machines use synchronized servo motors to achieve ±0.01mm precision at speeds exceeding 80 cups per minute. IoT-enabled models include:

- Real-time dashboards monitoring raw material usage and machine health

- Automated tooling changeovers that cut setup time by 65%

- Predictive maintenance algorithms detecting component wear 72+ hours before failure

These systems integrate with factory networks via Industry 4.0 protocols, allowing automatic alignment of production schedules with inventory levels. Centralized data collection enhances responsiveness by identifying inefficiencies and dynamically rerouting tasks during peak demand.

Cost Efficiency, Profitability, and Scalability in Large-Scale Operations

Analyzing Cost Efficiency in Automated Paper Cup Manufacturing

Paper cup machines that run automatically can cut down on manufacturing costs anywhere from 40 to 50 percent when compared with those semi-automated setups. This happens mainly because they use materials so precisely and require far less manpower than older methods do. According to some recent studies looking at automation costs back in 2024, factories running full automation get around 85% usage out of their materials while manual operations only manage between 60 and 65%. The savings don't stop there either. These modern machines come equipped with energy efficient servo motors plus heat recovery systems which means they consume significantly less electricity for every thousand cups made. For businesses trying to keep expenses low, these kinds of upgrades represent substantial savings over time.

Linking Production Efficiency to Increased Profitability

Higher output speeds directly boost profitability—machines producing 80–85 cups per minute fulfill large orders three times faster than traditional methods. Optimized scalable models can increase gross margins by 18–22% (Automation Trends Report 2023), freeing capital for R&D or market expansion while maintaining competitive pricing.

High-Capacity Machines and Margins: Overcoming Energy Cost Challenges

Advanced paper cup machines consume 30% less energy per unit than older models. Variable-frequency drives and intelligent thermal management adjust power use based on real-time demand, helping manufacturers preserve 12–15% profit margins even during energy price volatility.

Scalability of Modern Machines for Evolving Production Demands

Modular automation allows factories to scale output by 200–300% without expanding facilities. Interchangeable tooling and software-controlled settings enable quick transitions between cup sizes and materials, minimizing downtime. Manufacturers using upgradable systems report 25% faster response to seasonal demand spikes compared to those relying on fixed-capacity equipment.

Applications in the Foodservice and Beverage Industry

Meeting High-Volume and Hygiene Standards With Automatic Paper Cup Solutions

Paper cup machines automate what restaurants need most these days clean operations and fast production. They cut down on human touch points by around 94% when compared to hand made cups, which means fewer chances of germs getting into the product. These machines can crank out between three thousand and four thousand cups every hour, making them essential for places that serve thousands of customers daily. The forming process happens at controlled temperatures so the cups stick together properly without leaving any glue behind something that matters a lot for coffee shops and fast food outlets. Meeting those FDA standards isn't just paperwork either it's actually important stuff that keeps customers safe while drinking their morning brew or afternoon soda.

Growing Demand Driven by Foodservice and Beverage Sector Needs

The market for paper cups looks set to expand at around 6.8% each year until 2028 according to Grand View Research from last year, mainly because people around the world keep moving away from reusable containers to single use options. Big manufacturers have started implementing smart quality checks powered by artificial intelligence these days. These systems can spot when a cup's walls are too thin and toss them out automatically if they fall below 0.3 millimeters thick. Such exact measurements really matter for big coffee shops like Starbucks who need something like half a billion cups every year. The new technology also cuts down on wasted materials by about 18 percent compared to older manufacturing techniques, saving both money and resources in the long run.

FAQ

What is the primary function of an automatic paper cup machine?

An automatic paper cup machine integrates steps from feeding raw materials to printing and forming cups, automating the manufacturing process to increase consistency and reduce manual labor.

How do automatic paper cup machines ensure hygiene?

They minimize human touchpoints during production, reducing the risk of contamination and helping manufacturers adhere to FDA food safety guidelines.

What are the cost benefits of using automated paper cup machines?

Automated machines typically cut manufacturing costs by 40-50% due to precise material usage and reduced manpower needs, increasing material usage efficiency from 60-65% to about 85%.

How do these machines impact environmental sustainability?

They support a shift towards eco-friendly packaging by reducing plastic waste and offer quicker ROI and reduced production costs, contributing to sustainability efforts.

Why is there an increasing demand for paper cups in the market?

The growing demand is driven by trends towards single-use options, expanding foodservice industries, and consumer preferences for hygienic and eco-friendly packaging.

Table of Contents

- The Role of Automatic Paper Cup Machines in Mass Production

- Enhanced Efficiency and Precision Through Automation

- Workflow Optimization and Production Line Integration

- Cost Efficiency, Profitability, and Scalability in Large-Scale Operations

- Applications in the Foodservice and Beverage Industry

-

FAQ

- What is the primary function of an automatic paper cup machine?

- How do automatic paper cup machines ensure hygiene?

- What are the cost benefits of using automated paper cup machines?

- How do these machines impact environmental sustainability?

- Why is there an increasing demand for paper cups in the market?