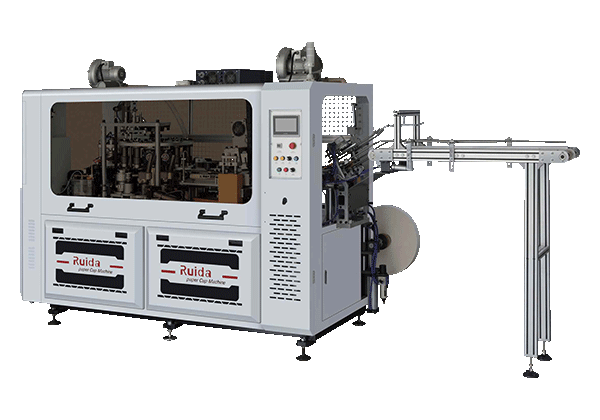

Boost Production Efficiency with a High-Speed Paper Cup Machine

How HighSpeed Paper Cup Machine Boosts Output Rates

The latest generation of paper cup manufacturing equipment can crank out between 120 to 160 cups every single minute, which cuts down on what each cup costs to produce by roughly 10 to maybe even 15 percent when compared to older techniques. These machines come equipped with sophisticated servo controls and multiple workstations that handle everything from shaping the cups to adding prints and sealing the bottoms all in one smooth flow, so there aren't those annoying slowdowns that used to plague production lines. Some factories have implemented AI for quality checks too, and according to a report from Globenewswire back in 2025, this tech supposedly catches defects about 35% better than before. The real benefit though is not just catching problems early but keeping the whole line running nonstop most of the time. All this attention to detail means less wasted materials going into landfills while still hitting those maximum production numbers that keep customers happy.

Automation Features Reducing Manual Labor Dependency

Automation significantly reduces reliance on manual labor in paper cup manufacturing:

- Robotic arms manage feeding and stacking, cutting manual interventions by 60%.

- Real-time monitoring autonomously adjusts temperature and pressure settings, requiring only 3-5 personnel per shift (2024 industry analysis).

- Self-diagnostic tools predict maintenance needs up to 48 hours in advance, preventing unplanned downtime during critical cycles.

Case Study: Leading Manufacturer's 30% Output Increase

An Asian paper cup producer increased output by 30% after upgrading to high-speed automation. Servo-driven forming stations and machine learning algorithms reduced cycle times by 22%, while maintaining 99.2% cup uniformity. Optimized heating systems lowered energy consumption per 1,000 cups by 18%, demonstrating that speed and sustainability can coexist without trade-offs.

Comparative Analysis: Traditional vs. High-Speed Cup Manufacturing

| Metric | Traditional Machines | HighSpeed Machines | Improvement |

|---|---|---|---|

| Output (cups/hour) | 5,400 | 14,400 | 167% |

| Labor per shift | 8-10 workers | 3-5 workers | 60% reduction |

| Energy use (kWh/1k cups) | 8.7 | 6.3 | 28% savings |

| Defect rate | 2.1% | 0.4% | 81% lower |

Data from recent operational studies shows high-speed machines outperform traditional models across all key efficiency metrics, particularly in markets requiring rapid scalability.

Achieve Significant Cost Savings with Automated HighSpeed Paper Cup Machine Operations

Reduced Operational Costs Using Automated HighSpeed Paper Cup Machine

High speed automation slashes labor costs anywhere from 35 to almost half, taking care of forming, sealing, and stacking tasks with very little hands-on work needed. The combination of built-in sensors and programmable logic controllers helps manufacturers save around 18 percent on wasted materials across their packaging lines, which obviously brings down what they spend on raw goods. Looking at staffing requirements tells another story too. Older semi-auto systems typically need between three and five workers running them all day long, whereas newer fully automated setups only require one person to monitor operations. That kind of difference adds up fast financially speaking, cutting roughly seven thousand two hundred dollars out of monthly payroll expenses just for labor costs alone.

Energy Efficiency and Long-Term Maintenance Benefits

Machines running on synchronous motor tech actually eat up about 22 percent less power than regular models, which translates into roughly four thousand eight hundred dollars saved each year per unit based on those Energy Star numbers from 2023. When it comes to efficiency ratings, brushless DC motors paired with servos hit around 85%, whereas older induction motors barely reach 60%. Companies that stick to proactive maintenance routines tend to get their equipment lasting about 40% longer on average. And for those plants using predictive analytics tools, unexpected shutdowns drop down somewhere near 62% less frequently according to what various maintenance departments have reported across different facilities.

Total Cost of Ownership: Why HighSpeed Machines Offer Better ROI

Although high-speed machines have an initial cost premium of 20-25%, their 7-year total cost of ownership is 35% lower. A 2023 ROI study of 87 manufacturers reveals:

| Cost Factor | Traditional Machine | HighSpeed Machine |

|---|---|---|

| Annual Energy Cost | $9,400 | $6,900 |

| Labor per Shift | $18/hr | $8/hr |

| Defect Rate | 3.2% | 0.8% |

This efficiency advantage grows with scale: facilities operating three or more high-speed machines reach breakeven 14 months faster than those using legacy systems.

Ensure Superior Product Quality and Consistency

High-speed paper cup machines maintain product integrity even at accelerated production rates. By integrating advanced engineering with intelligent monitoring, these systems deliver consistent quality across large batches without sacrificing efficiency.

Precision Engineering in HighSpeed Paper Cup Machine Ensures Uniformity

Laser-guided alignment and servo-controlled forming ensure ±0.1mm dimensional accuracy, minimizing variations common in manual operations. Packaging industry benchmarks (2024 Flexible Packaging Report) confirm 99.8% cup-to-cup consistency. Automated adhesive application maintains precise glue patterns, preventing leaks and reducing material waste by 18% versus conventional methods.

Real-Time Monitoring Systems Minimize Defect Rates

Vision inspection systems perform 240 quality checks per minute, detecting flaws such as improper seams or surface defects. When leading manufacturers adopted AI-driven defect detection, rejected batches dropped by 34% while sustaining production speeds of 400 cups/minute. These systems automatically adjust parameters if deviations exceed 0.05mm tolerances, enabling continuous, hands-free operation.

Industry Paradox: Speed vs. Quality - How HighSpeed Machines Resolve It

Advanced synchronization enables 22% faster cycle times than traditional machines while enhancing quality:

| Performance Metric | Traditional Machine | High-Speed Machine |

|---|---|---|

| Cups/Minute | 120 | 360 |

| Defect Rate | 2.1% | 0.4% |

| Energy Consumption | 8.2 kW | 5.6 kW |

Predictive maintenance prevents wear-related issues, while closed-loop feedback optimizes performance in real time. Data shows quality consistency improves by 15% when machines operate above 300 cups/minute due to stabilized thermal conditions and reduced human interaction.

Support Business Growth with Scalable HighSpeed Paper Cup Machine Solutions

HighSpeed Paper Cup Machine as a Growth-Ready Investment

The new high speed machines can boost production by anywhere from 200 to 400 percent without needing any changes to existing facilities, which makes them great options for companies looking to expand their markets. These aren't just one trick ponies like older equipment was. Businesses can actually upgrade their capacity bit by bit through simple software updates or adding modules as needed something really important for companies aiming to grow at least 15% each year. A recent look at the industry in 2024 shows that factories with these flexible systems scale up operations about half again as fast compared to places stuck with traditional machinery. This matters a lot when switching to newer products such as biodegradable cups that many consumers want now.

Modular Design Allows Easy Integration into Existing Lines

Modular architectures reduce integration time by 60% compared to fixed systems, allowing new forming stations or QC modules to be added in under eight hours. This plug-and-play capability minimizes downtime during upgrades–a crucial benefit for 24/7 operations. One manufacturer saved $18,000 annually in reconfiguration costs by adopting modular high-speed systems.

Adapting to Market Demand Fluctuations with Flexible Production Speeds

The machine lets operators tweak output from around 80 to 220 cups per minute while still keeping quality intact, which helps match production levels to what customers want seasonally. When we ran tests last quarter, this adaptability meant we hit 98 percent of orders on time during busy seasons but saved nearly a third on energy costs when things slowed down. The system comes with preset programs that make switching between different products a breeze. This really pays off when companies want to jump on special projects or collaborate with brands for limited edition packaging runs without having to reconfigure everything from scratch.

These capabilities make high-speed paper cup machines strategic assets for companies pursuing aggressive growth while maintaining operational stability. Industry leaders report 27% higher customer retention after implementing scalable systems compared to fixed-capacity setups.

Promote Sustainability Through Eco-Friendly HighSpeed Paper Cup Machine Processes

Reduced Material Waste via Optimized HighSpeed Paper Cup Machine Processes

Servo-driven precision cutting reduces raw material waste by 18-22% compared to conventional models (LinkedIn 2024). Real-time sensor adjustments correct paper alignment instantly, minimizing misprints and defective units. These optimizations help manufacturers meet strict environmental standards while sustaining outputs exceeding 200 cups per minute.

Support for Eco-Friendly Materials Without Compromising Speed

Top-tier machines now process biodegradable PLA coatings and recycled paperboard at full operational speed. This eliminates the historical trade-off between sustainability and throughput, enabling brands to replace up to 150 million single-use plastic cups annually with compostable alternatives.

Lower Carbon Footprint Through Energy-Efficient Manufacturing

Smart energy recovery systems reduce power consumption by 30-35% per unit produced. Combined with modular designs that minimize thermal emissions during forming, high-speed machines generate a 25% smaller carbon footprint over a five-year lifecycle (LinkedIn 2024).

| Metric | Conventional Machines | HighSpeed Machines | Improvement |

|---|---|---|---|

| Material Waste Rate | 12-15% | 3-5% | 67% reduction |

| Energy Use/Cup | 0.018 kWh | 0.012 kWh | 33% savings |

| CO2 Emissions (Annual) | 85 metric tons | 60 metric tons | 29% reduction |

Automated quality controls and standardized workflows ensure environmental gains are achieved without sacrificing speed, effectively debunking the myth that sustainability compromises industrial efficiency.

FAQs

-

How many cups can a high-speed paper cup machine produce?

A high-speed paper cup machine can produce between 120 to 160 cups per minute.

-

What are the labor advantages of using a high-speed paper cup machine?

These machines use automated features, requiring fewer personnel per shift—only about 3 to 5 workers compared to traditional methods that might use 8 to 10 workers.

-

Can high-speed paper cup machines handle biodegradable materials?

Yes, advanced machines can process biodegradable PLA coatings and recycled paperboard at full operational speed.

-

How does automation impact material waste?

Servo-driven precision cutting and real-time sensor adjustments reduce raw material waste by 18-22%.

Table of Contents

- Boost Production Efficiency with a High-Speed Paper Cup Machine

- Achieve Significant Cost Savings with Automated HighSpeed Paper Cup Machine Operations

- Ensure Superior Product Quality and Consistency

- Support Business Growth with Scalable HighSpeed Paper Cup Machine Solutions

- Promote Sustainability Through Eco-Friendly HighSpeed Paper Cup Machine Processes