From Manual Production to One-Operator Paper Cup Machine Lines

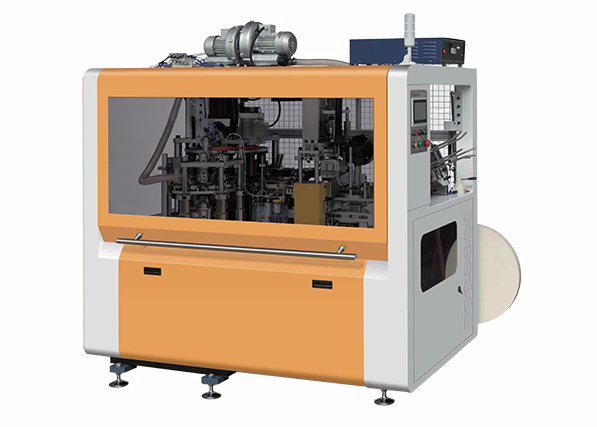

The latest generation of paper cup manufacturing equipment has completely changed how these products are made, swapping out those old manual processes for full automation. Back in the day, factories needed anywhere from five to eight workers during each shift just to handle materials, apply glue, and do quality inspections. But today's smart systems can operate smoothly with only a single tech on duty monitoring everything. The cost savings are impressive too, cutting down on direct labor expenses by as much as 82 percent according to recent studies. And despite all this efficiency gain, production rates still hit between 100 and 400 cups every minute, which is pretty remarkable when you think about it. Most manufacturers report that their bottom line looks much better after making this switch to automated production lines.

Reduced Training and Supervision Needs with Automated Systems

When it comes to cutting costs, automation really makes a difference in reducing those indirect labor expenses because it takes so much off operators' plates. Back in the day, workers needed special training to tweak cup forming settings or fix mechanical problems, but not anymore. These tasks are now handled automatically through things like PLCs and smart diagnostic systems that flag issues on their own. Training new staff has gone way down too - what used to take several weeks can be done in about 3 to 5 days now. And companies report needing around 70% fewer supervisors according to some industry data from 2023. Another big plus is predictive maintenance. Instead of waiting for parts to fail, these systems send alerts when components should be replaced, which means less downtime and fewer people watching over operations all day long.

Case Study: Labor Savings Using Automated Paper Cup Machine Systems

One major paper cup producer made the switch to complete automation recently, cutting down their workforce from 12 people working each shift down to only 3 who monitor the machines. The transition took about a year and half to implement properly, but it saved them around $325k annually on wages while making sure products came out consistently every time. They installed those fancy error proofing systems at the loading stations plus got real time defect detection going too. According to some internal efficiency reports they shared, this combo knocked their rejection rate down nearly 40 percent. What does all this mean for other companies? Well, now they can take some of those savings and put them into developing new products or expanding into different markets without having to worry about keeping up with production demands anymore.

Material Efficiency and Waste Reduction Through Precision Engineering

Modern paper cup machines use precision engineering to minimize waste and optimize resource use across three key areas:

Advanced Feeding Systems That Cut Paper Waste by Up to 18%

Servo-controlled feeding mechanisms align paperboard sheets with 0.2mm accuracy, reducing raw material waste by 12–18% compared to manual methods. Intelligent nesting algorithms maximize cup yield per sheet—a strategy validated in precision manufacturing trials.

Consistent Cup Formation Lowers Defect and Rejection Rates

Precision-ground molding dies ensure uniform wall thickness across batches, cutting cup deformation defects by 15%. This consistency prevents material losses equivalent to 23 reams of paper per 10,000 units, based on industry waste benchmarks.

Smart Design Minimizes Glue and Energy Use per Unit

Thermally regulated glue nozzles apply adhesive within 0.1mm tolerances, reducing consumption by 22% per cup. Simultaneously, energy recovery modules capture and reuse 65% of process heat, lowering annual power costs by $4,200 per machine in temperate climates.

Lower Maintenance and Downtime with Reliable Paper Cup Machine Units

Predictive Maintenance Features in Modern Paper Cup Machine Systems

IoT sensors and machine learning algorithms enable modern machines to predict component wear by analyzing real-time vibration and temperature data. This approach reduces unplanned downtime by 40%, allowing maintenance to be scheduled during off-peak hours and avoiding costly production interruptions.

Durable Components Extend Machine Lifespan and Reduce Repairs

High-grade steel cutting dies and ceramic-coated heating elements withstand 3–5 times more production cycles than standard parts. PLC systems enhance durability through adaptive speed control that minimizes mechanical stress. Facilities using these components reported 18% lower annual repair costs, according to a 2022 industry report.

Case Example: Long-Term Performance of Industry-Leading Paper Cup Machine Designs

One manufacturer maintained 98.5% operational uptime over three years by combining modular hardware with AI-driven maintenance protocols. Their system automatically orders replacement parts when anomalies are detected, reducing inventory holding costs by 30%. This level of reliability is essential for meeting large retail contracts without delivery penalties.

Key design features reducing long-term costs:

- Self-lubricating guide rails requiring servicing only every 5,000 hours

- Tool-free quick-change mechanisms for die replacements (<5 minutes)

- Cloud-based performance dashboards accessible to remote technicians

Scalability and Output Consistency for Sustainable Cost Advantages

High-Speed Paper Cup Machine Lines Meet Growing Market Demand

Automated lines producing over 400 cups per minute allow manufacturers to scale output 12–18% faster than conventional systems, all while keeping labor costs below $0.02 per unit (Packaging Trends 2023). This capacity aligns with the 6.2% annual growth in disposable packaging demand, helping producers avoid costly overtime or additional shifts.

Uniform Quality Reduces Returns and Protects Brand Reputation

Laser-guided alignment systems help automated machines achieve defect rates below 0.8%, compared to 3–5% in semi-automated setups. This consistency has measurable financial benefits: a 2023 logistics study found it reduces shipping damage claims by 27% and customer return rates by 34%.

Modular Expansion Strategy Lowers Initial Investment Risk

Top manufacturers offer modular paper cup machines that support incremental upgrades for handles, double-walled insulation, or custom printing. This strategy enables producers to:

- Start with 150-cup/minute base units at 40% lower upfront cost

- Add capabilities during routine maintenance with zero downtime

- Achieve full ROI within 14 months—compared to 22 months for turnkey systems

A Midwest converter used this approach to scale from 2 million to 12 million cups monthly, avoiding $2.7 million in premature capital investment during early market testing.

FAQ Section

-

What are the benefits of automating paper cup machine operations?

Automation significantly reduces labor costs, increases production efficiency, enhances product quality, and minimizes waste through precision engineering. -

How does predictive maintenance benefit paper cup manufacturers?

Predictive maintenance reduces unplanned downtime, allows maintenance schedules during off-peak hours, and cuts production interruptions, enhancing overall operational efficiency. -

What is the potential cost savings for manufacturers using automated systems?

Manufacturers can save up to 82% on labor costs and achieve significant reductions in material waste, maintenance costs, and energy consumption. -

How do modular paper cup machine systems provide an advantage?

They offer flexibility for incremental upgrades, reduce initial investment risks, and have quick returns on investment while allowing easy adaptation to market changes.

Table of Contents

- From Manual Production to One-Operator Paper Cup Machine Lines

- Reduced Training and Supervision Needs with Automated Systems

- Case Study: Labor Savings Using Automated Paper Cup Machine Systems

- Material Efficiency and Waste Reduction Through Precision Engineering

- Lower Maintenance and Downtime with Reliable Paper Cup Machine Units

- Scalability and Output Consistency for Sustainable Cost Advantages

- FAQ Section