Advancing Efficiency: Automation and High-Speed Production in Paper Cup Machines

Rising Demand for High-Speed Production in the Paper Cup Industry

The paper cup business worldwide is expanding pretty fast these days, clocking in around 5.2% growth each year from 2023 through 2035 according to recent estimates. Food chains and delivery services are placing bigger orders than ever before, so manufacturers need equipment that can crank out thousands of cups per hour just to keep up. Many companies have started investing in specialized machinery that produces over 4,000 units an hour flat out. What's interesting is how this boom coincides with changing consumer preferences toward eco friendliness. A recent survey found that nearly seven out of ten people actually want compostable options instead of regular plastic cups when grabbing coffee on the go. This shift makes sense given current environmental concerns, but it also presents real challenges for producers trying to balance speed with sustainability requirements across their operations.

How Automation Enables Output of 5,000+ Cups per Hour

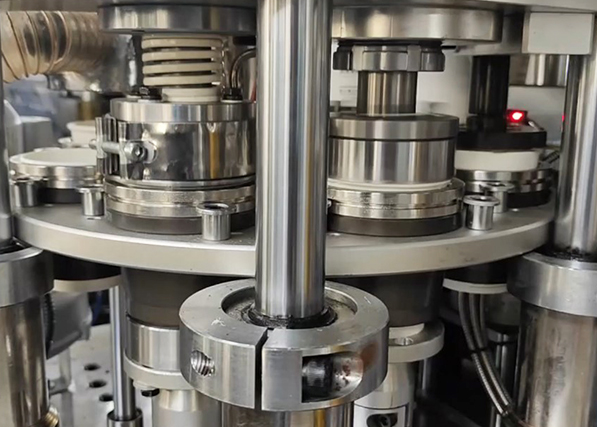

The latest generation of paper cup manufacturing equipment now incorporates servo driven systems along with Internet of Things sensors, allowing production speeds well beyond what was possible before. Some models can actually produce over five thousand cups each hour, which is pretty impressive when compared to older machines. Setup times have been dramatically reduced thanks to automated tool changing mechanisms that save about seventy percent of the time previously spent on manual adjustments. Meanwhile, multiple workstations operate in sync to handle all aspects of cup production including forming, sealing, and attaching the base within less than three quarters of a second per unit. Industry reports from early 2024 indicate that these technological advancements enable continuous operation around the clock, maintaining quality standards with defect occurrences staying consistently low at roughly half a tenth of a percent or better.

Case Study: Zhejiang RUIDA Machinery’s Fully Automatic Line at 6,000 Cups/Hr

Zhejiang RUIDA Machinery deployed a 12-station automated line with AI-guided quality inspection, achieving 6,000 cups/hour and 99.8% dimensional accuracy through laser-calibrated dies. The system reduced energy consumption by 18% compared to earlier models, proving that speed and sustainability can coexist.

From Manual to Fully Automatic: The Industry’s Shift Toward Precision Engineering

The shift from semi-automatic to fully automatic systems has lowered labor costs by 40–60%. Modern machines feature self-diagnostic protocols that predict bearing failures more than 72 hours in advance, minimizing unplanned downtime. These advancements reflect broader smart manufacturing trends, with 83% of packaging producers prioritizing automation for supply chain resilience (PMMI 2023).

Smart Manufacturing: AI and IoT Integration in Paper Cup Machine Operations

Modern paper cup manufacturing is embracing Industry 4.0, where AI and IoT integration reduce unplanned downtime by up to 40% through predictive analytics (Ponemon 2023). This digital transformation enhances production continuity and reduces waste—key advantages amid rising demand for sustainable packaging.

The Rise of Smart Factories in the Packaging Sector

Smart factories use interconnected IoT sensors and edge computing to monitor temperature, humidity, and vibration across production lines. Real-time thermal monitoring ensures precise adhesive curing during cup sealing, cutting defects by 22% compared to manual methods.

AI-Powered Predictive Maintenance Reducing Downtime by 40%

Machine learning algorithms analyze performance data to anticipate component wear. One manufacturer reported a 37% drop in bearing failures after implementing AI-driven maintenance, saving over 6,000 production hours annually.

Cloud-Based Control Systems for Remote Machine Management

Centralized dashboards allow operators to adjust parameters remotely, enabling quick transitions between cup sizes or materials. Cloud integration also synchronizes multiple machines, ensuring consistent output during continuous 24/7 operations.

AI-Driven Quality Control and Real-Time Defect Detection

Vision systems with 0.02mm resolution inspect cups at 120 frames/second—ten times faster than human inspectors. A 2024 packaging industry study found AI-powered detection improved first-pass yield rates by 18% in high-speed environments exceeding 8,000 cups/hour.

Sustainable Innovation: Eco-Friendly Design and Energy-Efficient Paper Cup Machines

Consumer Demand Driving Sustainable Packaging Solutions

Environmental awareness is reshaping production, with 63% of foodservice businesses favoring suppliers using sustainable machinery (LinkedIn 2023). This trend responds to both consumer preferences and tightening regulations around ecological impact.

Energy-Efficient Motors and Low-Waste Production Technologies

New machines use direct-drive motors and servo controls to cut energy consumption by up to 30% versus hydraulic systems. Advanced blanketing optimizes paperboard use, reducing material waste, while closed-loop cooling recycles 90% of process water.

Case Study: RUIDA Machinery’s Green Series Cutting Energy Use by 25%

RUIDA’s Green Series achieves a 25% energy reduction via solar-compatible inverters and heat recovery modules. Aligned with U.S. Department of Energy benchmarks for industrial decarbonization, it proves high-speed production (6,000 cups/hour) can meet eco-efficiency standards.

Enabling Biodegradable Linings and Compostable Coatings Through Advanced Machinery

Next-gen machines apply plant-based PLA linings and water-based barrier coatings without compromising seal integrity. Precision temperature control allows thinner applications, reducing polyethylene usage by 40% while maintaining rigidity and leak resistance.

Modular Machine Design for Recyclable and Alternative Material Compatibility

Modular tooling enables rapid switching between recycled fiberboard, bamboo pulp, and agricultural waste substrates. This adaptability prepares manufacturers for raw material fluctuations and circular economy requirements, including configurations that accept 100% post-consumer waste.

Customization and Market Growth: Shaping the Future of Paper Cup Machine Adoption

Brand Differentiation Through Custom Cup Shapes, Sizes, and On-Demand Printing

More than seventy two percent of folks running restaurants want cups they can customize, which has really pushed forward what's possible with digital printing and those modular tools. These days, the newer machines can make cups with different shapes at the top, handles that fit better in hands, and company logos printed right there while keeping things moving fast enough for busy periods. According to something published last year about this sector, switching to these modular systems means changing from one design to another takes around two thirds less time than it used to with older methods. That kind of flexibility matters a lot when dealing with holiday promotions or special events where quick turnaround is essential.

Innovations in Functional Design: Insulation, Leak-Proof Seams, and Flexible Tooling

Dual-wall insulation and ultrasonic sealing are now standard to meet performance expectations. Servo-controlled crimping heads create leak-proof seams in 0.8-second cycles, while adaptive tooling handles biodegradable PLA linings and recycled stocks. These features support the 31% annual growth in compostable cup demand (Packaging Digest 2023).

Market Expansion: Projected Growth Beyond USD 1.8 Billion by 2035

The global paper cup machine market is projected to grow at 6.8% CAGR through 2035, driven by expansion in Asia-Pacific, particularly a $740 million manufacturing surge. Energy-efficient models like RUIDA’s Green Series account for 40% of new installations, thanks to regenerative braking systems that lower energy use (Machinery Today 2024).

Emerging Markets: Rapid Adoption in Southeast Asia and Beyond

Southeast Asia installs over 320 high-speed cup lines annually to meet booming demand from bubble tea and coffee markets. Vietnam’s packaging sector grew 19% YoY in 2023, with automated cup machines cutting labor costs by 60% in large factories (ASEAN Packaging Report 2024).

Scaling Innovation Through R&D and Cross-Industry Collaboration

Leading manufacturers invest 12–15% of revenue in R&D partnerships with material science firms. These collaborations have produced machines capable of processing algae-based coatings and nano-cellulose reinforcements—critical for compliance with the EU’s Single-Use Plastics Directive.

FAQ

What is fueling the demand for high-speed paper cup production?

The growing demand is driven by an increase in orders from food chains and delivery services, as well as a consumer shift towards eco-friendly, compostable paper cups.

How does automation improve production efficiency in paper cup machines?

Automation allows for the production of over 5,000 cups per hour by incorporating advanced systems such as servo-driven mechanisms and IoT sensors, reducing setup times, and maintaining high quality with minimal defects.

How are energy-efficient technologies being implemented in paper cup production?

Machines are using direct-drive motors and servo controls for better energy efficiency, alongside closed-loop cooling systems that recycle water, all of which contribute to reduced energy consumption.

How does AI and IoT integration benefit paper cup manufacturing?

These technologies enable predictive analytics to drastically reduce unplanned downtime, improve maintenance through AI-driven systems, and facilitate remote machine management via cloud-based systems.

Why is sustainable innovation important in paper cup production?

Sustainable innovation aligns manufacturers with consumer preferences and regulatory requirements. Advanced technologies allow for biodegradable linings and energy-efficient processes.

Table of Contents

- Advancing Efficiency: Automation and High-Speed Production in Paper Cup Machines

- Smart Manufacturing: AI and IoT Integration in Paper Cup Machine Operations

-

Sustainable Innovation: Eco-Friendly Design and Energy-Efficient Paper Cup Machines

- Consumer Demand Driving Sustainable Packaging Solutions

- Energy-Efficient Motors and Low-Waste Production Technologies

- Case Study: RUIDA Machinery’s Green Series Cutting Energy Use by 25%

- Enabling Biodegradable Linings and Compostable Coatings Through Advanced Machinery

- Modular Machine Design for Recyclable and Alternative Material Compatibility

-

Customization and Market Growth: Shaping the Future of Paper Cup Machine Adoption

- Brand Differentiation Through Custom Cup Shapes, Sizes, and On-Demand Printing

- Innovations in Functional Design: Insulation, Leak-Proof Seams, and Flexible Tooling

- Market Expansion: Projected Growth Beyond USD 1.8 Billion by 2035

- Emerging Markets: Rapid Adoption in Southeast Asia and Beyond

- Scaling Innovation Through R&D and Cross-Industry Collaboration

-

FAQ

- What is fueling the demand for high-speed paper cup production?

- How does automation improve production efficiency in paper cup machines?

- How are energy-efficient technologies being implemented in paper cup production?

- How does AI and IoT integration benefit paper cup manufacturing?

- Why is sustainable innovation important in paper cup production?