Understanding the Paper Cup Machine: Definition and Core Function

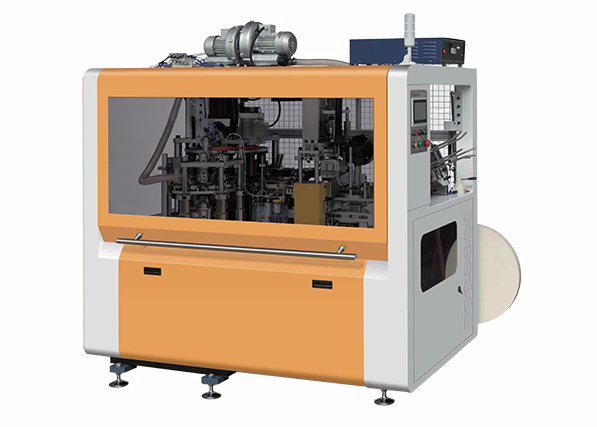

What is a Paper Cup Machine?

Paper cup machines take the guesswork out of making disposable cups, transforming rolls of polyethylene coated paper into finished containers through careful folding, sealing processes, and shaping techniques. Manufacturers can produce all sorts of cups with these machines including those for hot drinks, cold beverages, and even food grade packaging made from leak proof laminated materials. According to Statista data from 2023, some modern systems can crank out around 150 cups every single minute. For businesses looking to get started, there are options ranging from semi automatic models suitable for smaller operations right up to fully automated versions designed for large scale manufacturing facilities.

The Role of Disposable Paper Cup Machinery in Modern Packaging

The demand for disposable paper cup machines is rising worldwide as businesses seek cleaner options than traditional plastics. According to Statista data from 2023, the market for biodegradable packaging should see annual growth around 7.8% right up until 2030. These machines let manufacturers produce cups that meet FDA standards while cutting down on material waste by roughly 15 to 20 percent when compared with older manufacturing techniques. Plus, they run efficiently which helps companies in various sectors cut their environmental impact. We're seeing this technology adopted heavily in places like coffee shops, fast food chains, and even hospitals where hygiene remains a top concern alongside eco considerations.

How Does a Paper Cup Machine Work from a Functional Standpoint?

- Material Feeding: Coated paper rolls unwind smoothly into the system via tension-controlled rollers.

- Printing & Cutting: Branding is applied using food-safe inks, followed by high-precision die-cutting into cup blanks.

- Cup Forming: Blanks wrap around heated mandrels (160–180°C), where seams are sealed under pressure.

- Bottom Sealing: Circular bases are fused to cup walls using heat and pneumatic pressure.

- Rim Curling: Mechanical curling wheels roll the top edge to enhance rigidity and user comfort.

- Quality Control: Vision systems inspect each cup for defects such as misprints or seal flaws and automatically reject non-conforming units.

This integrated workflow ensures consistent output, with advanced models incorporating IoT sensors to monitor temperature stability and real-time performance metrics.

Key Components of a Paper Cup Machine and Their Functions

Modern paper cup machines combine precision engineering with automation to achieve production rates of 80–150 cups per minute while maintaining strict quality standards.

Unwinding Unit and Raw Material Feeding Mechanism

The unwinding unit feeds coated paper rolls into the machine using tension-regulated rollers that prevent wrinkles and misalignment. According to a 2023 packaging industry report, advanced feeding systems reduce material waste by 18% compared to manual processes.

Printing and Cutting Module in the Production Process

Integrated flexographic printing stations apply branding with food-grade inks, while rotary die-cutters shape the paper into accurate cup wall and base profiles. These modules maintain tolerances within ±0.2 mm, ensuring uniformity across high-volume runs.

Cup Forming, Bottom Sealing, and Rim Curling Stations

Three core stations finalize the cup’s structure:

- Forming drums shape flat blanks into cylindrical walls.

- Sealing jaws use heat (160–180°C) and pressure to bond the bottom securely.

- Curling wheels create a rolled rim for durability and improved handling.

Heating Elements and Pressure Control for Reliable Sealing

Ceramic heating elements and pneumatic systems ensure consistent, leak-proof seals. Machines from leading manufacturers use closed-loop controls to maintain temperature accuracy within ±2°C, critical for reliable adhesion of polyethylene layers.

Automated Discharge and Quality Inspection Systems

Infrared sensors and vision-based inspection systems scan every cup for defects like uneven seals or printing errors. Approved cups move to stacking conveyors, while rejected units are diverted automatically—reducing quality control labor costs by 40% in large-scale operations.

The Paper Cup Production Process: From Raw Materials to Final Product

Step-by-Step Overview of How a Paper Cup Making Machine Functions

Paper cup machines convert coated rolls into finished products through five synchronized stages. First, the unwinding system delivers material to printing modules, where flexographic presses apply branding. High-speed die-cutting then produces precise blanks, which proceed to forming stations capable of processing over 200 cups per minute (Sustainable Packaging Institute 2023).

Material Preparation: Coated Paper Rolls and Feeding Dynamics

Production starts with FSC-certified paperboard lined with polyethylene (PE) or polylactic acid (PLA) for liquid resistance. Tension control systems maintain feed rates between 30–50 meters per minute, while sensors detect imperfections such as wrinkles or thickness deviations exceeding ±0.02 mm.

Precision Cutting and High-Speed Shaping Techniques

Hydraulic punching units cut printed sheets into cup profiles with ±0.1 mm accuracy. The cup bodies are then formed around heated mandrels (160–180°C), achieving structural strength capable of withstanding 1.2 kg of vertical compression.

Sealing with Heat and Pressure for Leak-Proof Performance

At the bottom sealing station, 12–15 bar pressure and temperatures reaching 220°C fuse the PE-coated layers into a watertight base. Innovations like laser-assisted sealing improve consistency across temperature ranges (0–95°C) and reduce energy consumption by 18%.

Final Formatting: Rim Curling and Structural Reinforcement

Triple-stage curling heads roll the cup rims to a 270° angle, enhancing sidewall rigidity and drinking comfort. Integrated 5MP camera systems detect curling deviations greater than 0.3 mm, ensuring compliance with ISO 14001 standards for food-safe packaging.

Types of Paper Cup Making Machines and Their Technological Features

Manufacturing today relies on various machine setups depending on what needs to get done. Single head machines work great when companies need to make smaller runs or create custom designs, whereas multi head systems can crank out several cup sizes at once, which really boosts output numbers. When it comes to automation levels, there's a clear difference between semi automatic and fully automatic models based on how much hands on time operators need. Fully automated versions come packed with built in quality checks and can run non stop throughout shifts, something packaging industry experts highlighted in their 2024 reports. Looking at high capacity industrial equipment, these machines boast precision forming areas along with automated stacking functions, capable of churning out thousands upon thousands of cups every single hour. Specialized operations benefit from adjustable die cutting tech that lets manufacturers tweak sizes from tiny espresso cups all the way up to those big cold drink containers people grab on hot summer days.

Innovation and Efficiency in Modern Paper Cup Machine Operations

Advancements by Leading Manufacturers Like ZheJiang RUIDA Machinery Co., Ltd.

Leading manufacturers have started incorporating servo motors along with PLC control systems these days. This integration allows for much better precision while cutting down on energy consumption by around 15 percent compared to what we saw in previous generations of equipment. Meanwhile, modern production lines are getting multi functional they bring together printing, forming, and sealing all into a single continuous operation. As a result, factories can crank out products at speeds that are somewhere between 30 to maybe even 40 percent higher than before, and still keep product quality consistent across batches about 99 point something percent consistent anyway. All these improvements make it easier for companies to switch over to biodegradable materials as well, which fits right into the growing trend towards eco friendly packaging solutions that many consumers are demanding nowadays.

Energy Efficiency and Waste Reduction in Automated Systems

Laser-guided cutting and real-time adhesive monitoring reduce material waste to less than 2%. Thermal recovery systems reuse 25% of heat output, cutting annual carbon emissions by 12–15 metric tons per machine. Predictive maintenance algorithms decrease unplanned downtime by 80%, while automated lubrication reduces oil usage by 60%.

Smart Controls and IoT-Enabled Monitoring in Production

IoT-connected machines deliver detailed analytics on parameters like cup weight variance (±0.03g) and seal strength (≥98 kPa). Edge computing optimizes settings for varying paper grades, enabling 50% faster material changeovers. Remote diagnostics resolve 90% of technical issues within 45 minutes, according to 2023 smart manufacturing benchmarks.

Future Trends in Paper Cup Manufacturing Technology

Next-generation machines will adopt AI-powered quality control with hyperspectral imaging to identify microscopic coating defects. Modular designs will allow rapid reconfiguration for cup diameters (50–120mm) and paper weights (180–350 GSM). Water-based adhesive systems currently in pilot testing aim to eliminate VOC emissions by 2027 and achieve fully recyclable cup construction.

Frequently Asked Questions (FAQ)

What types of cups can a paper cup machine produce?

Paper cup machines can produce a variety of cups, including those designed for hot beverages, cold drinks, and food-grade packaging.

How do paper cup machines reduce material waste?

Paper cup machines utilize advanced feeding mechanisms and efficient sealing techniques to cut down on material waste by approximately 15 to 20 percent compared to older systems.

What advancements have been made in paper cup machine technology?

Recent advancements include the integration of servo motors and PLC control systems for better precision, reduced energy consumption, and the adoption of IoT sensors for real-time monitoring of production metrics.

Are paper cups produced by these machines biodegradable?

Yes, modern paper cup machines often produce cups that meet biodegradable standards, contributing to eco-friendly packaging solutions.

Table of Contents

- Understanding the Paper Cup Machine: Definition and Core Function

- Key Components of a Paper Cup Machine and Their Functions

- The Paper Cup Production Process: From Raw Materials to Final Product

- Types of Paper Cup Making Machines and Their Technological Features

- Innovation and Efficiency in Modern Paper Cup Machine Operations

- Frequently Asked Questions (FAQ)